Lightweight Steel Partition Walls: The Secret Weapon for Crafting Personalized Spaces

2025-05-19 15:57:32

1. Fundamental Understanding of Lightweight Steel Partition Walls

Lightweight steel partition walls are constructed using hot-dip galvanized light steel studs as the framework, paired with panel materials like gypsum board or cement fiberboard. Their core advantages lie in lightness, rapid construction, and design flexibility. They meet spatial partitioning needs while integrating multifunctional properties such as fire resistance, sound insulation, and seismic performance, making them a cornerstone solution for modern architectural space transformation.

2. Core Material Characteristics and Functional Combinations

2.1 Framing System: Light Steel Studs

Manufacturing: Rolled from hot-dip galvanized steel sheets, these studs offer high strength and corrosion resistance.

Types: Common types include ceiling tracks, floor tracks, and vertical studs, forming the wall’s supportive structure. Stud spacing can be adjusted to accommodate panels of varying thicknesses.

2.2 Panel Materials: The Key to Function and Aesthetics

Gypsum Board: Lightweight and easy to install, suitable for dry environments with basic fire and soundproofing capabilities.

Cement Fiberboard: Moisture-resistant, ideal for humid areas like kitchens and bathrooms.

Calcium Silicate Board: High fire resistance, meeting requirements for public buildings or high-fire-safety scenarios.

Decorative Panels: Options like wood-grain or metal panels enhance aesthetic appeal directly.

2.3 Insulating Materials: Performance Enhancers

Materials like rock wool or glass wool can be filled into stud cavities to boost sound insulation and thermal performance, elevating the wall’s overall functionality.

3. Core Advantages and Application Scenarios of Lightweight Steel Partition Walls

3.1 Space-Shaping Advantages

Thickness Efficiency: Walls are only 75–150mm thick, saving significant space compared to traditional brick walls and improving usable area ratios.

Modular Flexibility: Their modular structure supports rapid assembly/disassembly, ideal for dynamic office layouts or rental property renovations.

3.2 Versatile Performance

Fire Resistance: Board combinations can achieve 1–3 hours of fire resistance.

Sound Insulation: Filling cavities with acoustic materials can achieve high soundproofing levels, suitable for quiet spaces like bedrooms or conference rooms.

Seismic Resistance: Flexible connections enable resistance to high-intensity earthquakes, ensuring structural stability.

3.3 Application Scenarios

Residential: Interior partitions, separating walls, and loft mezzanines.

Commercial: Office partitions in office buildings, hotel room renovations, and exhibition hall dividers.

Schools, hospitals, and other projects prioritizing safety and construction efficiency.

4. Design and Construction Key Points: From Concept to Completion

4.1 Personalized Design Directions

Artistic Boundaries: Curved or angular stud structures create artistic spatial edges.

Custom Finishes: Panels can be spray-painted or laminated with decorative films to match diverse styles.

Integrated Functions: Combine with embedded cabinetry or piping systems for functional integration.

4.2 Construction Process and Critical Details

Substrate Preparation: Ensure wall flatness within acceptable tolerances; remove dust and loose particles to prevent misaligned studs.

Stud Installation: Fix studs at design intervals, ensuring verticality and reinforcing connections with specialized fittings.

Panel Installation: Leave gaps between board edges, fill with joint compound, and apply anti-crack tape to prevent future cracking.

Special Area Treatments:

Humid Environments: Add concrete cills at the base, use waterproof panels, and seal joints.

Heavy Loads: Install reinforcements between studs.

5. Purchase Pitfall Avoidance Guide: Material and Specification Selection

5.1 Stud Selection Key Points

Opt for hot-dip galvanized studs with a wall thickness ≥1.0mm; check flatness and straightness to avoid deformation risks.

5.2 Panel Material Matching Principles

Environment-Based Selection: Gypsum board for dry areas, cement fiberboard for humid zones, and calcium silicate board for high-fire-safety needs.

Budget Considerations: Choose standard or custom decorative panels based on financial constraints.

5.3 Specification Adaptation Recommendations

For walls ≤3m high, use 60-series studs with 12mm panels for adequate strength.

For taller partitions (>3m), upgrade stud series and reduce vertical stud spacing for enhanced stability.

6. Core Differences from Traditional Walls

Lightweight steel walls employ dry construction, significantly shortening timelines compared to traditional brick walls. They are lightweight, highly adaptable, and cost-effective. In contrast, brick walls involve complex construction processes, are difficult to demolish, and generate substantial waste.

7. Conclusion: Redefining Spatial Possibilities

Lightweight steel partition walls are not just functional space dividers but also vehicles for personalized design. To maximize their advantages, select high-quality materials aligned with your scenario, style, and budget, and ensure professional installation. This approach will help you create ideal spaces that blend aesthetic value with practical performance.

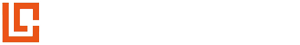

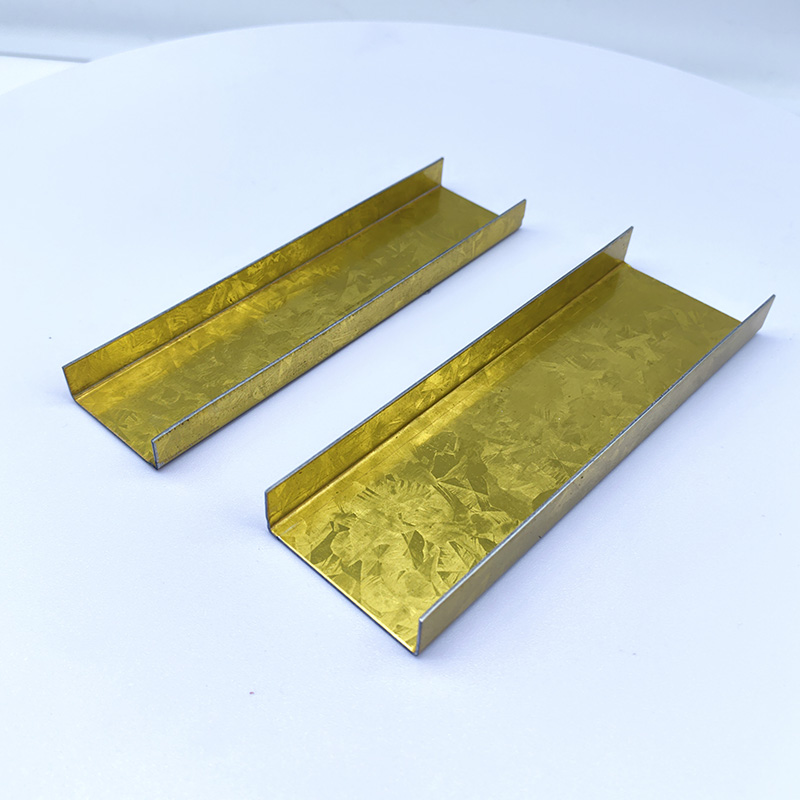

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

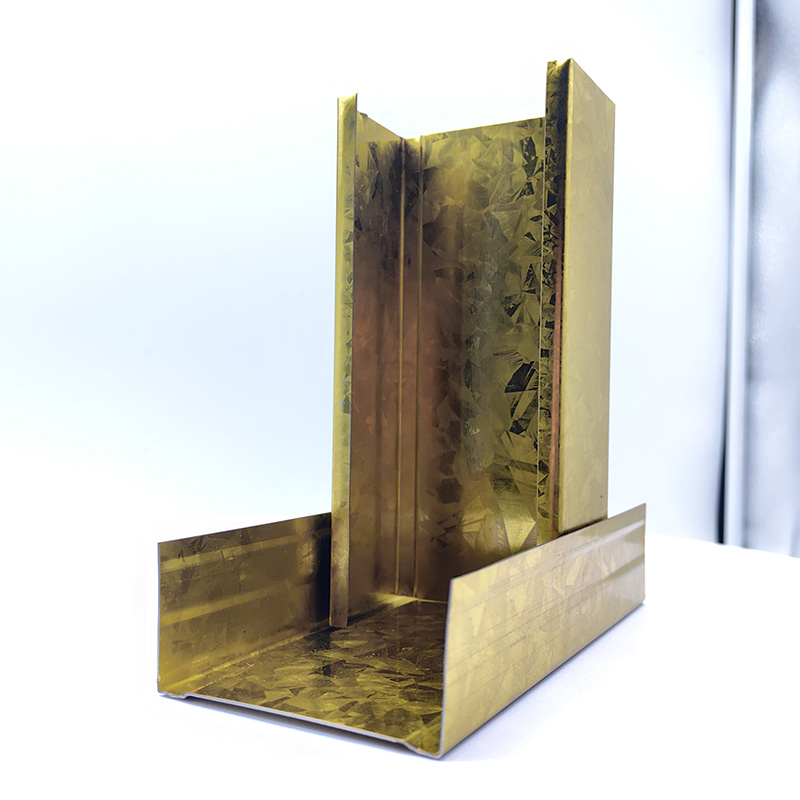

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

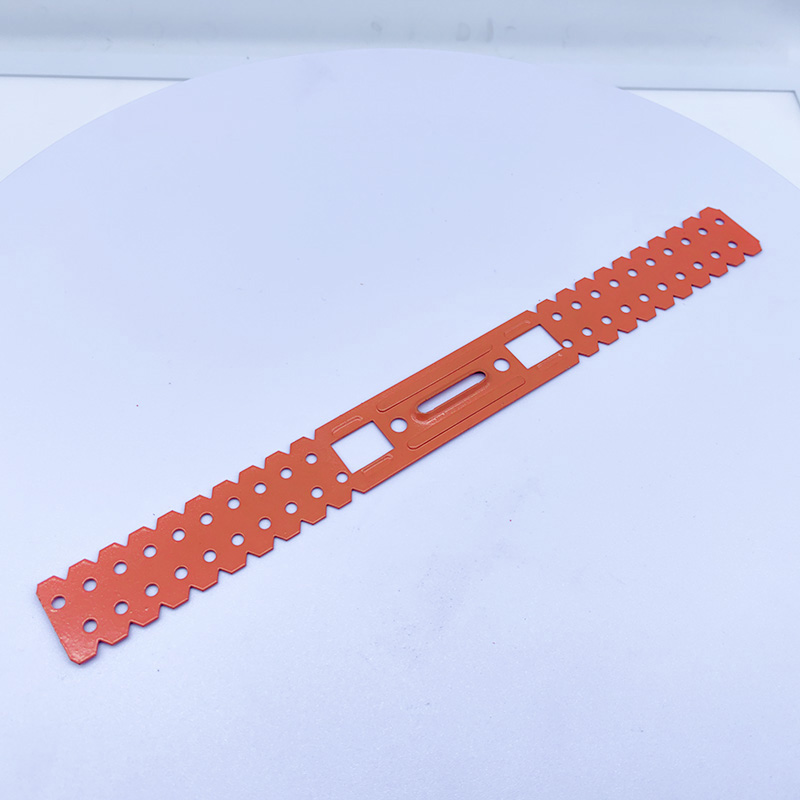

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

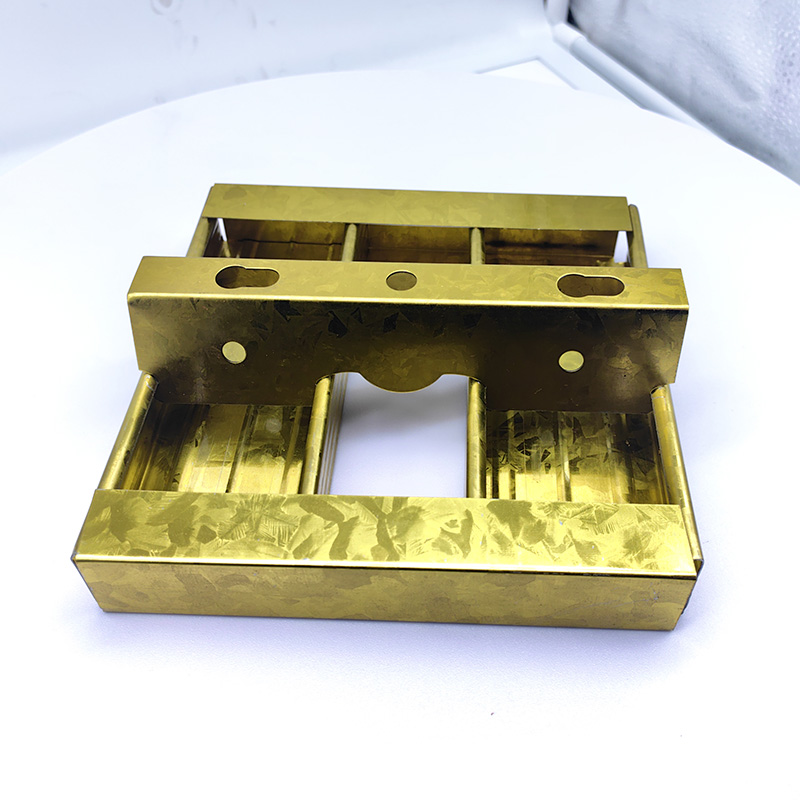

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...