Selection Guide for Ceiling Channel Materials: A Comparison of Light Steel vs. Aluminum in Terms of Load-Bearing Capacity, Corrosion Resistance, and Cost

2025-07-06 04:59:25

In ceiling construction projects, ceiling channels serve as the critical framework supporting the ceiling surface layer, and their material selection directly impacts the project's quality and service life. Currently, light steel channels and aluminum channels are the mainstream options in the market due to their respective advantages. How can one make a scientific decision based on load-bearing requirements, corrosion resistance, and cost budget? This article will conduct a comparative analysis from three core dimensions to provide you with a reference for material selection.

I. Basic Understanding of Light Steel and Aluminum Ceiling Channels

(1) Light Steel Channels

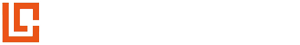

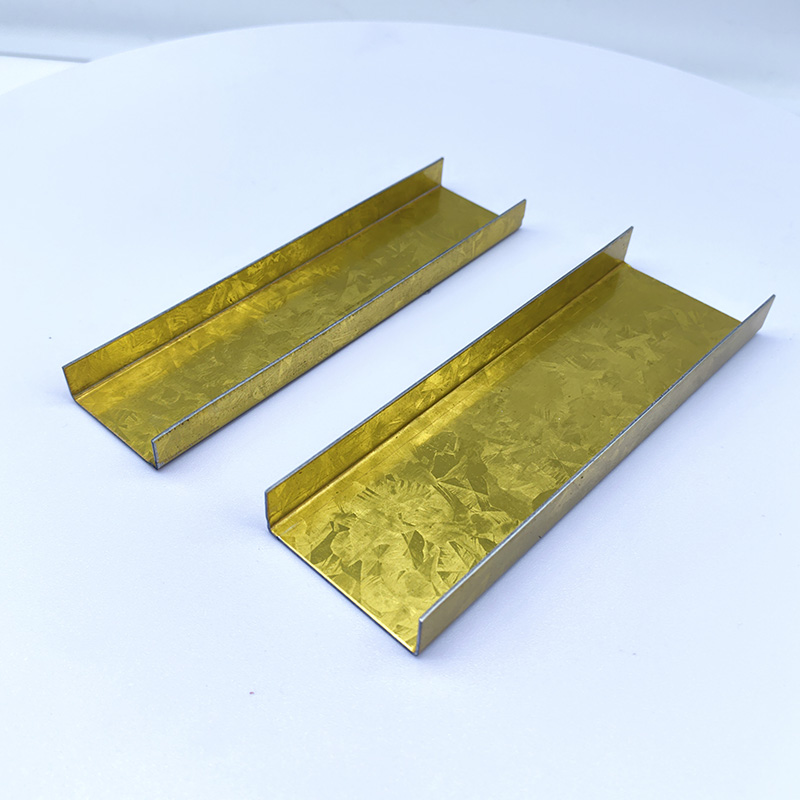

Light steel channels are primarily manufactured from galvanized steel strips or thin steel plates, with common structural types including U-shaped and C-shaped profiles. Due to their cost-effectiveness and ease of installation, they are widely used in ordinary residential buildings, commercial office spaces, and other scenarios, making them one of the most popular channel materials in the market.

(2) Aluminum Channels

Aluminum channels are made from specific alloy compositions (such as 6063 aluminum alloy) through an extrusion molding process. Compared to other materials, aluminum channels feature low density and excellent corrosion resistance, making them suitable for high-end commercial spaces, humid environments, and other areas where aesthetics and weather resistance are crucial.

II. Comparative Analysis of Core Dimensions

(1) Load-Bearing Performance Comparison

Light steel channels, leveraging the high strength of steel, exhibit outstanding rigidity and load-bearing capacity, making them suitable for supporting heavier ceiling surface materials. Although aluminum channels are lightweight, they can still meet the load-bearing requirements of most scenarios through reasonable structural design, particularly advantageous in weight-sensitive building structures.

In practical applications, the specifications of the channels (such as thickness and spacing) significantly affect their load-bearing performance. For instance, thicker channels and smaller installation spacing generally provide higher load-bearing limits. Therefore, users need to comprehensively evaluate factors such as the weight of the ceiling surface material and the height of the space to select the appropriate channel specifications.

(2) Corrosion Resistance Comparison

Light steel channels primarily rely on their galvanized coating for corrosion protection, with the zinc layer effectively isolating the steel from air and moisture, thereby delaying rusting. Aluminum channels benefit from the naturally formed dense oxide film on aluminum's surface, which provides inherent corrosion resistance, especially in humid, acidic, or alkaline environments.

From a long-term perspective, aluminum channels require less maintenance due to their superior corrosion resistance, while light steel channels may need periodic inspections and repairs if the galvanized coating is damaged, potentially increasing maintenance costs and frequency.

(3) Cost Comparison

In terms of material costs, aluminum channels generally have a higher market price than light steel channels due to the special nature of their raw materials and processing techniques. During construction, aluminum channels, being relatively soft, are easier to install, potentially saving labor time. However, light steel channels, with their mature installation systems and widespread market application, also offer competitive construction costs.

Considering material procurement, construction expenses, and long-term maintenance costs, light steel channels are more cost-effective in the short term, while aluminum channels, despite their higher initial costs, demonstrate cost advantages over their entire lifecycle due to their long service life and low maintenance requirements.

III. Selection Recommendations for Different Scenarios

(1) Residential Renovation

For ordinary home renovations, if the requirements for ceiling aesthetics and moisture resistance are moderate, light steel channels are an ideal choice due to their high cost-effectiveness and reliable load-bearing performance. If the budget allows and long-term performance is a priority, aluminum channels can provide a better experience in terms of corrosion resistance and aesthetics.

(2) Commercial Spaces

Commercial venues often seek a balance between elegance, aesthetics, and durability. Aluminum channels, with their lightweight nature and diverse styling options, are frequently used to create modern or high-end decorative styles. In large-scale commercial spaces where cost sensitivity is a concern, light steel channels, combined with proper design, can also meet load-bearing and decorative requirements.

(3) Special Environments

In humid areas such as bathrooms and kitchens, or in coastal environments with high salt spray, the strong corrosion resistance of aluminum channels becomes a primary advantage. For public buildings with high fire safety requirements, fire-resistant light steel channels that comply with relevant standards can be selected to balance safety and economy.

IV. Tips for Avoiding Pitfalls in Material Selection

(1) Avoiding Common Misconceptions

Some users may mistakenly believe that "thicker channels are always better" or "blindly pursue low prices." In reality, overly thick channels may increase the building load, while low-priced products may have hidden risks such as substandard materials or inadequate corrosion protection, requiring careful selection.

(2) Mastering Identification Techniques

When selecting light steel channels, the quality can be initially assessed by observing the color and integrity of the galvanized coating. For aluminum channels, attention should be paid to whether the surface is smooth and free from cracks or blisters to avoid purchasing inferior recycled aluminum products.

(3) Following Procurement Principles

Prioritize brands with good reputations and complete qualifications. Clearly specify material specifications, quality standards, and after-sales terms in the contract. During the acceptance process, carefully verify the quantity, appearance, and quality certification documents of the channels.

V. Conclusion

Both light steel channels and aluminum channels have their advantages and disadvantages: light steel channels excel in cost-effectiveness and broad applicability, while aluminum channels stand out in corrosion resistance, aesthetics, and performance in special scenarios. Through this comparative analysis of the three core dimensions of load-bearing capacity, corrosion resistance, and cost, we hope to assist you in making a scientific and reasonable decision regarding ceiling channel selection based on your actual needs and budget. If you have any further questions, feel free to leave a comment for discussion.

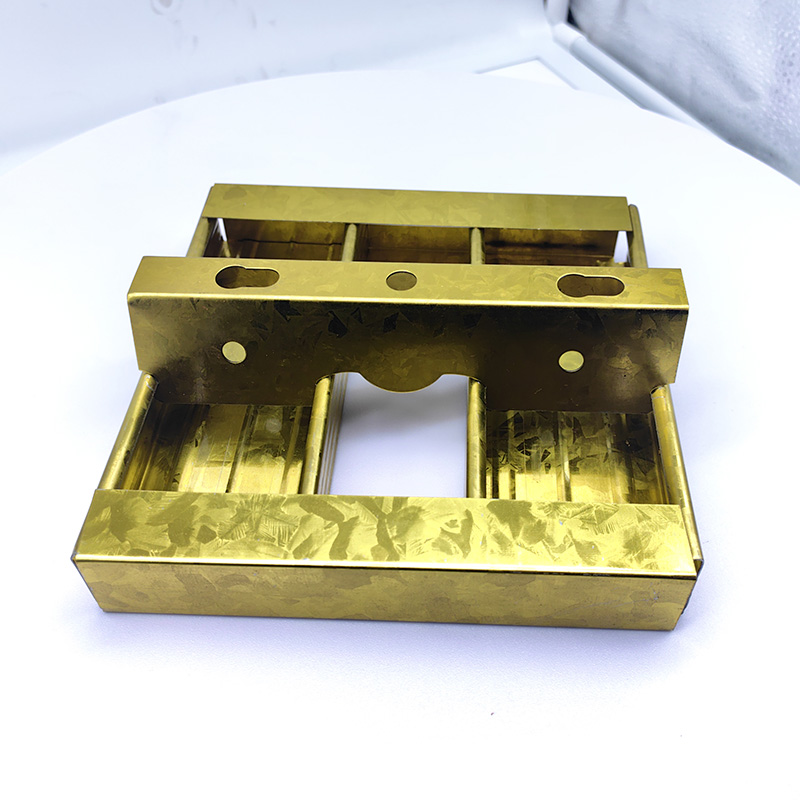

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

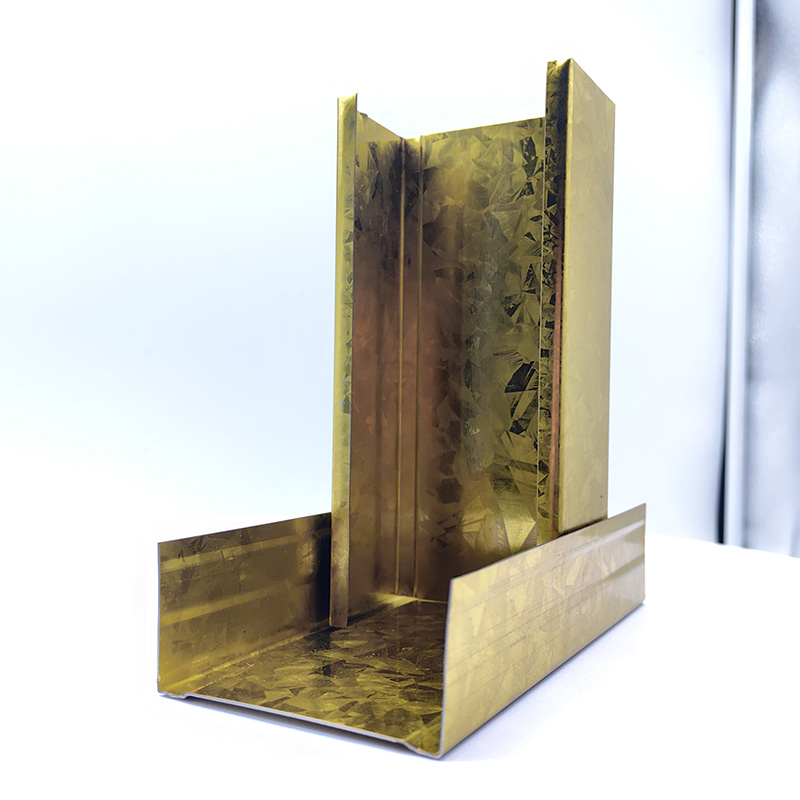

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...