How to Choose the Right Metal Wall Corner Guards? Here's the Answer!

2025-05-15 16:50:53

Wall corners are inevitably prone to collisions and scratches in daily life, which not only mars their appearance but may also cause damage to the wall structure. Metal wall corner guards, renowned for their high strength and durability, have emerged as a favored option for safeguarding wall corners in both residential and public settings. However, with the market brimming with a diverse array of metal corner guard products, how can one pinpoint the most fitting choice? This article aims to furnish you with a professional purchasing guide, delving into aspects such as material characteristics, specifications, key installation points, and beyond.

I. Core Performance Comparison: Judging the Quality of Metal Corner Guards

1.1 Protective Performance: Strength Determines Durability

The protective performance of metal corner guards is the primary consideration. Among them, stainless steel corner guards have high hardness and strong impact resistance, making them suitable for high-traffic public areas or wall corners prone to collisions. Aluminum alloy corner guards are lightweight and have good toughness. They can withstand impacts while avoiding damage to furniture or people due to excessive hardness, making them more suitable for daily family use. Meanwhile, the thickness of the corner guard also affects its protective effect. Generally speaking, thicker corner guards can withstand greater impacts, but it's necessary to weigh the actual usage scenario - slightly thicker models can be chosen for areas with frequent collisions, while regular thickness is sufficient for ordinary areas.

1.2 Aesthetic Compatibility: Integration of Style and Details

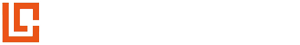

The color and shape of metal corner guards should coordinate with the home decor style. For a minimalist modern style, pure-colored metal corner guards in silver, black, etc., with clean lines, can be chosen to avoid overshadowing the overall design. For neo-Chinese or retro styles, metal corner guards with a bronze-like or wood-grain texture can be paired to add a classical charm. In addition, some metal corner guards feature special designs such as arcs or waves, which can inject an artistic touch into the space and enhance the overall design aesthetic while providing protection.

1.3 Durability and Maintenance: The Key to Worry-Free Use

Metal materials inherently possess anti-aging and corrosion-resistant advantages, but there are still differences in durability among different metals. Stainless steel corner guards are wear-resistant, corrosion-resistant, and have a long service life. Daily cleaning only requires wiping with a damp cloth. Although aluminum alloy corner guards have slightly inferior corrosion resistance, they can also effectively extend their service life through surface oxidation treatment. During maintenance, avoid using sharp tools to scratch them. Compared with other materials, metal corner guards are less prone to deformation and fading, making them more worry-free for long-term use.

1.4 Environmental Protection and Safety: Guaranteeing a Healthy Home

High-quality metal wall corner guards are made from environmentally friendly materials and do not release harmful substances such as formaldehyde, meeting home health standards. For families with children or pets, it is recommended to choose metal corner guard models with rounded edges and no sharp corners to reduce the risk of injury from bumps and ensure that the materials are non-toxic and harmless, safeguarding family safety.

II. Specification Selection: Practical Tips for Matching Needs

2.1 Length Specifications: Precise Selection Based on Wall Corners

Metal corner guards come in a variety of length specifications, and the appropriate one should be selected based on the actual height of the wall corner. If only for局部修补 (partial repair) of damaged wall corners, short-length corner guards can be cut. If whole-wall corner protection is needed, long-specification products are preferred to reduce splicing gaps and enhance the integrity and aesthetics of the protection. When measuring, use a tape measure to vertically measure from the top of the wall corner to the floor, leaving a 1-2 cm margin to ensure that the corner guard fully covers the wall corner.

2.2 Width and Thickness Specifications: Balancing Protection and Aesthetics

The width of the corner guard affects the visual effect. Narrower corner guards (such as 2-3 cm wide) are more inconspicuous and suitable for spaces pursuing a minimalist style. Wider corner guards (over 5 cm wide) offer a larger protective area and stronger decorative effects, serving as visual accents in the space. In terms of thickness, as mentioned above, it needs to be selected in combination with the usage scenario. Regular household use of 1-2 mm thick metal corner guards can balance protection and aesthetics.

III. Installation Points: Ensuring Stability and Durability

3.1 Preparation of Installation Tools

The following tools should be prepared in advance for installing metal wall corner guards: a tape measure (for measuring length), scissors or a cutting machine (for cutting the corner guard), special glue or nails (for fixing the corner guard), a level (for calibrating verticality), and a rag (for cleaning the wall).

3.2 Detailed Installation Steps

Clean the wall corner: Use a rag to remove dust, oil stains, and debris from the wall surface, ensuring that the wall corner is dry and clean to enhance the adhesion between the corner guard and the wall.

Measure and cut: According to the measured length of the wall corner, use scissors or a cutting machine to cut the metal corner guard. The cut should be flat to avoid burrs affecting the installation effect.

Fix and install:

Glue sticking: Apply special glue evenly on the back of the corner guard, align it with the wall corner, and slowly press it into place, holding it for a few minutes until it is initially fixed. When sticking, proceed from top to bottom to avoid air bubbles and displacement.

Nail fixing: For areas with high load-bearing requirements, nails can be used for auxiliary fixing. Drill holes in the corner guard at regular intervals and nail it into the wall. When drilling, be careful to avoid hidden facilities such as electrical wires.

Adjust and calibrate: During the installation process, use a level to check the verticality and flatness of the corner guard at any time. If any skewing is found, adjust it promptly to ensure that the corner guard fits tightly against the wall corner and has straight lines.

3.3 Installation Precautions

Avoid applying excessive force during installation to prevent scratching the wall surface. Use sharp tools with caution to prevent injury. In addition, there are slight differences in the installation of corner guards made of different metal materials. For example, stainless steel corner guards have high hardness, and professional tools are required for cutting and drilling. Aluminum alloy corner guards are relatively soft in texture, and excessive bending during installation should be avoided to prevent deformation.

IV. Purchasing Summary: Comprehensive Consideration and Rational Decision-Making

When selecting metal wall corner guards, it is necessary to comprehensively weigh factors such as the usage scenario, decor style, and budget: High-strength stainless steel corner guards are preferred for high-traffic areas; aluminum alloy corner guards can be considered for home environments to balance protection and aesthetics; In terms of style compatibility, pure-colored and minimalist models are versatile, while special-shaped models have a stronger design sense. Meanwhile, pay attention to the product's environmental protection rating and safety details to ensure stable installation. By following the above points, I believe you can easily select the suitable metal wall corner guard to provide long-term protection for your wall corners!

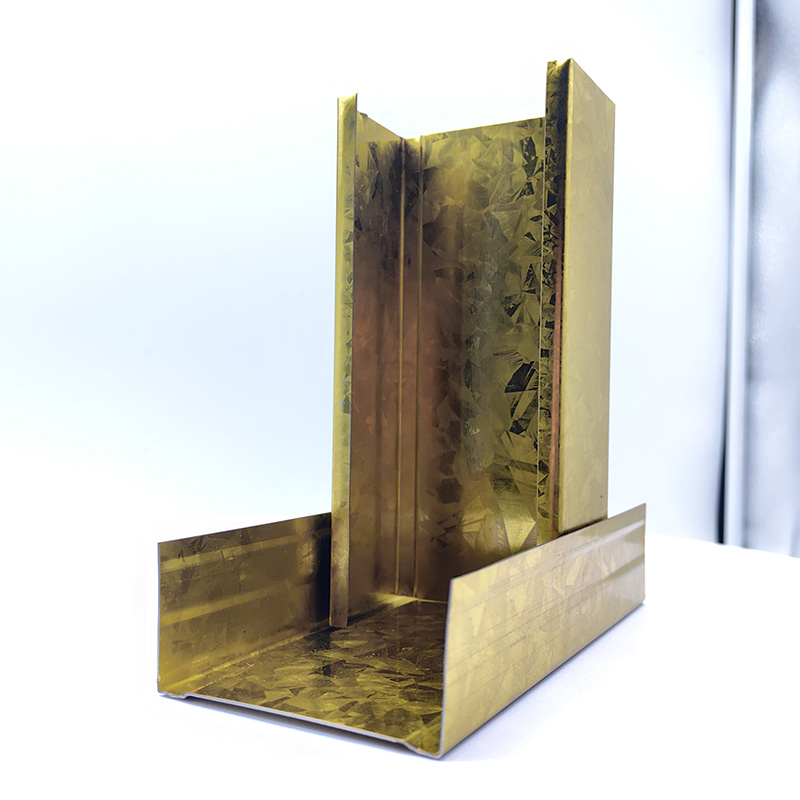

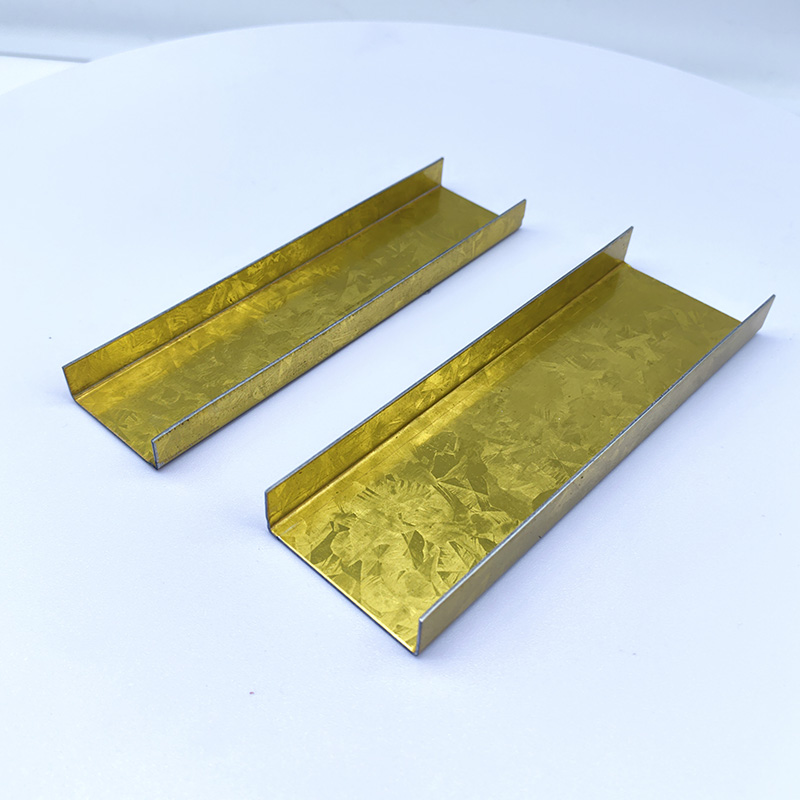

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

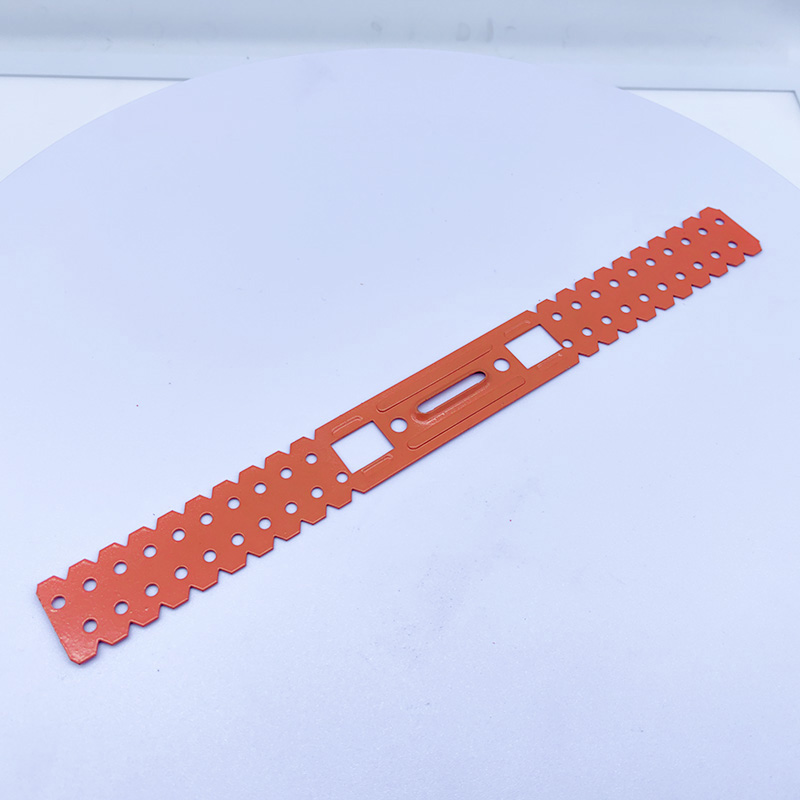

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...