Comprehensive Analysis of Construction Specifications for Ceiling Channels: A Guide to Avoiding Pitfalls from Spacing Design to Load-Bearing Calculations

2025-07-09 07:39:31

In ceiling construction projects, ceiling channels serve as the core framework supporting the ceiling surface layer, and their construction specifications directly impact the safety, durability, and aesthetics of the ceiling. Whether you are a professional construction worker or a homeowner planning a DIY renovation, mastering the entire process from preliminary preparation to final acceptance, as well as avoiding common construction pitfalls, are crucial for ensuring project quality. This article will delve into the key points of construction specifications and pitfall avoidance methods, starting from core aspects such as spacing design and load-bearing calculations.

I. Preliminary Preparation Specifications

(1) Material Acceptance Standards

Before construction, the quality acceptance of channels and accessories is fundamental. For light steel or aluminum channels, it is essential to inspect whether the surface is flat, free from deformation or corrosion, and ensure that the material meets the design requirements. For accessories such as hangers and connectors, check whether their specifications and thickness meet the standards to avoid potential load-bearing hazards due to insufficient accessory strength. Additionally, strictly verify the material specifications against the design drawings to prevent delays and quality issues caused by size discrepancies.

(2) Confirmation of Construction Conditions

The base ceiling surface is the foundation for channel installation, and its flatness error must be within the allowable range, with sufficient load-bearing capacity. If the base surface is uneven, it should be addressed in advance. Furthermore, since the pre-embedding of water and electricity pipelines often intersects with channel construction, it is necessary to coordinate the construction sequence in advance to avoid conflicts between pipeline and channel installations. The environmental conditions at the construction site, such as temperature, humidity, and ventilation, also affect construction quality. For example, high humidity may cause light steel channels to rust, necessitating reasonable scheduling of construction time.

II. Detailed Explanation of Core Construction Specifications

(1) Spacing Design Specifications for Channels

Different ceiling materials have varying requirements for channel spacing. For instance, heavier gypsum boards require denser channel spacing to ensure load-bearing capacity, while lighter aluminum ceiling tiles can have slightly wider spacing. Generally, main channels and sub-channels should follow a scientific ratio principle, with main channels bearing the primary load and sub-channels assisting in fixing the ceiling surface layer. For curved or irregularly shaped ceilings, channel spacing should be adjusted according to the design curvature to ensure the stability and aesthetics of the shape.

(2) Load-Bearing Calculation Specifications

Ceiling loads are divided into static loads (such as the self-weight of ceiling materials) and dynamic loads (such as wind pressure and maintenance loads). Accurately identifying and calculating load types is the premise for designing the load-bearing capacity of channels. The load-bearing capacity of channels is closely related to the number and specifications of hangers. Excessively large hanger spacing or insufficient hanger diameter may lead to inadequate load-bearing capacity. Additionally, the type of building structure (such as frame structure or brick-concrete structure) also restricts the load-bearing design of channels, which requires calculation and adjustment based on the actual building conditions.

(3) Installation Operation Specifications

During hanger installation, ensure that their perpendicularity meets the standards to avoid uneven force distribution due to inclination. Meanwhile, control the hanger spacing to comply with the design requirements to ensure uniform dispersion of ceiling loads. The connection between main and sub-channels should adopt appropriate fixing methods, such as screw fixation or snap-fit connections, and ensure connection strength. The installation of edge channels directly affects the overall flatness and sealing of the ceiling. Use a level to assist in calibration to ensure neat edges without gaps.

III. Guide to Avoiding Construction Pitfalls

(1) Common Construction Pitfalls

Neglecting channel spacing specifications during construction may lead to ceiling deformation or cracking in the later stage. Incorrect estimation of ceiling load-bearing capacity, such as underestimating the weight of surface materials, can pose safety hazards. Failing to reserve expansion joints during installation may cause cracking due to thermal expansion and contraction of channels and ceiling materials with temperature changes.

(2) Error Correction Solutions

If channel spacing is found to be too wide, auxiliary channels can be added or hanger density increased for remediation. For load-bearing capacity deficiencies, the channel structure should be reinforced, such as increasing channel thickness or replacing with high-strength connectors. If misalignment occurs during installation, the incorrect parts should be promptly removed and reworked according to specifications to avoid leaving quality hazards.

(3) Key Points for Quality Self-Inspection

During construction, use a straightedge to inspect the flatness and perpendicularity of channels. Check the stability of load-bearing structures through shaking tests or simulated load applications. For concealed works, such as the fixation of channels to the base surface and hanger connections, focus on acceptance before closing the ceiling surface layer to ensure compliance with specifications.

IV. Explanation of Construction Differences in Different Scenarios

In residential renovations, construction processes can be appropriately simplified while ensuring safety, but attention should be paid to balancing cost and quality. Commercial spaces have higher requirements for construction efficiency and aesthetics, necessitating the prioritization of channel solutions that are easy to install and offer diverse styling options. In humid environments such as bathrooms and kitchens, channels with stronger moisture-proof and corrosion-resistant properties should be selected, and edge sealing should be enhanced to prevent moisture erosion.

V. Conclusion

Construction specifications for ceiling channels cover the entire process from material acceptance, spacing design, to installation pitfall avoidance, and each step's standard operation is crucial for ensuring the quality of ceiling projects. By mastering the construction key points and pitfall avoidance techniques in this article, both construction professionals and homeowners can effectively improve construction quality and avoid later maintenance costs and safety risks.

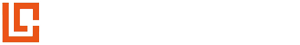

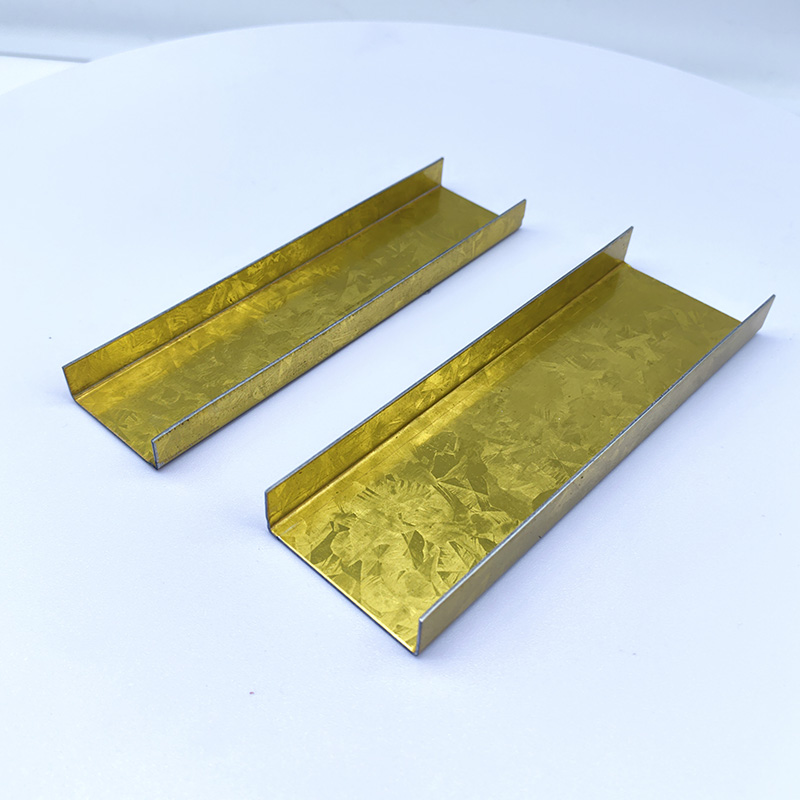

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

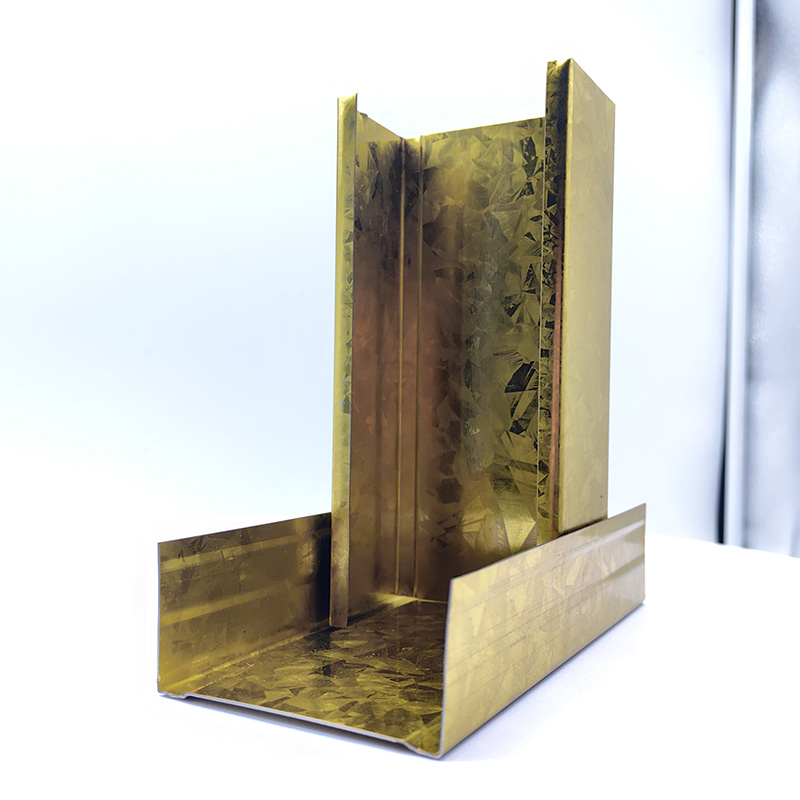

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

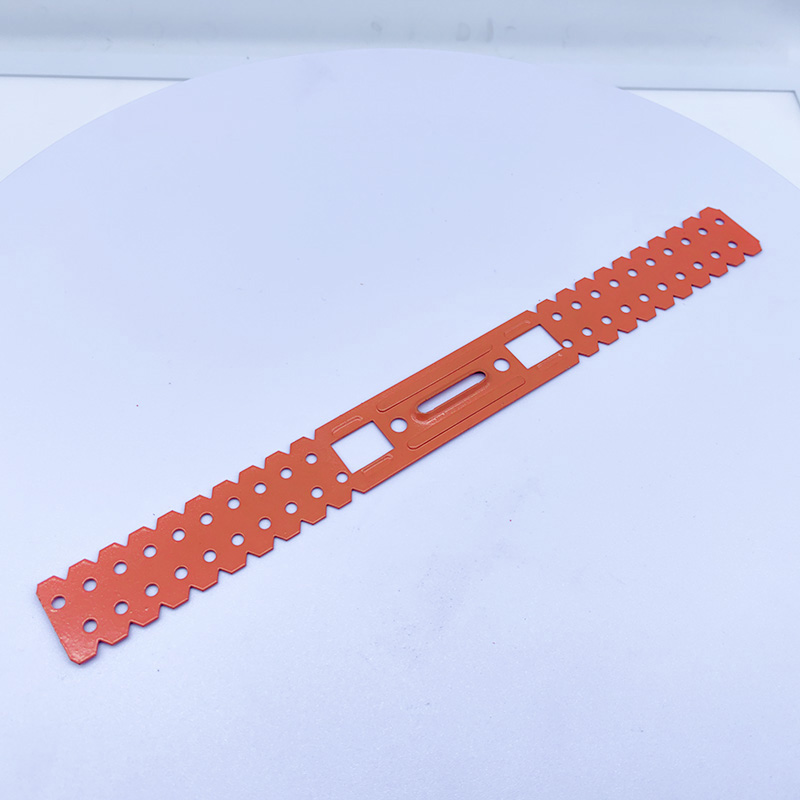

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...