Analysis of the Load-Bearing Principle of Ceiling Grids: Key Technologies for Ensuring Space Safety

2025-07-15 11:23:13

In the fields of architecture and interior design, ceilings are not only core elements for beautifying spaces but also structural foundations for carrying lighting, ventilation, fire protection, and other equipment. Among them, the load-bearing design of ceiling grids is crucial for determining the overall safety of the space. This article will delve into the core aspects of ceiling grid load-bearing technology from the perspectives of mechanical principles, material properties, structural optimization, and international standards, providing professional references for the industry.

I. Mechanical Foundations: Application of Triangular Stable Structures

The load-bearing principle of ceiling grids is essentially an optimized design of mechanical structures. Traditional ceilings disperse loads through a hierarchical structure of "hanger rods - main runners - cross runners," while modern light steel framing systems further introduce triangular stable structures. By shortening the length of hanger rods or adding auxiliary supports, the resistance to deformation is significantly enhanced.

1. Counter-Support Technology: Dispersing Axial Tension

In high-rise buildings or renovation projects of historical buildings, when the length of hanger rods exceeds 1.5 meters, horizontal steel frames or diagonal braces need to be installed below the main runners to form multiple triangular units. This design can disperse the pressure at the ceiling's vertex to auxiliary support points, effectively resisting lateral forces such as wind pressure and equipment vibrations. For example, in a renovation project of a historical building, the use of counter-support technology reduced the risk of ceiling sagging by 80% while meeting the requirements for protecting the original structure.

2. Transfer Floor Structures: Optimizing the Layout of Heavy Equipment

In large commercial spaces such as airports and subway stations, ceilings need to carry heavy equipment like ventilation ducts and fire sprinklers. Transfer floors, through a combination of steel frames and hanger rods, directly transfer the equipment loads to the building's structural layer instead of relying solely on the hanger rods for support. In a project at an international convention and exhibition center, a modular steel frame transfer floor was adopted, achieving a balance between equipment loads and decorative functions, with a ceiling flatness error controlled within ±1 mm.

International Research Support:Research conducted by the Technical University of Munich in Germany indicates that triangular stable structures can enhance the anti-deformation capability of ceiling systems by more than three times, making them particularly suitable for earthquake-prone regions or high-rise buildings.

II. Material Properties: Advantages of Light Steel Framing in Strength and Durability

The load-bearing capacity of ceiling grids is closely related to material performance. Thanks to its excellent balance of mechanical performance and durability, light steel framing is widely adopted in a broad range of modern ceiling systems.

1. Material Standards and Load Design

Light steel framing is typically made of galvanized steel sheets (with a thickness of 0.5 - 1.2 mm), and its yield strength can reach 300 - 550 MPa. According to international standards, the load design of light steel framing should meet the following requirements:

· Uniform Load: Not less than 50 kg/m² (suitable for office spaces);

· Concentrated Load: The single-point load-bearing capacity should exceed 100 kg (suitable for the installation of heavy lighting fixtures);

· Fire Resistance Rating: Not less than 60 minutes (in compliance with building fire protection regulations).

2. Surface Treatment and Anti-Corrosion Processes

In humid environments (such as basements and bathrooms), light steel framing needs to be treated with hot-dip galvanizing or epoxy resin coatings to prevent rusting. In a commercial complex project in a coastal city, galvalume steel sheets were used, and their corrosion resistance was verified through salt spray tests, with a service life exceeding 20 years.

International Standard References:The standards of the American Society for Testing and Materials (ASTM) stipulate that the thickness of the galvanized layer on light steel framing should be ≥ 12 μm to ensure long-term stability in C3-level corrosive environments.

III. Structural Optimization: From Single Load-Bearing to Multi-Functional Integration

The design of modern ceiling grids has transcended traditional frameworks and is moving towards the integration of ventilation, sound insulation, and decoration.

1. Ventilation Grid Design: Enhancing Space Comfort

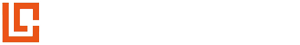

In scenarios such as machine rooms and kitchens, ceiling grids need to balance ventilation and load-bearing. For example, by using U-shaped box runners with perforated designs, air circulation can be promoted while the steel frame transfer floor disperses equipment loads. Optimized ventilation grid designs allow for significant improvement in airflow without compromising structural integrity, especially in equipment-intensive environments.

2. Integration of Sound Insulation and Fire Protection

In places with high acoustic requirements such as hotels and hospitals, ceiling grids need to be filled with sound-insulating materials like glass wool or rock wool. In high-end acoustic applications, composite ceiling systems incorporating sound-absorbing and fire-resistant materials were employed to achieve NRC ≥ 0.85 while meeting Class A fire protection standards.

International Certification Systems:The EU's CE certification requires that the sound insulation performance of ceiling systems should comply with the EN ISO 10140 standard, and the fire protection rating should reach Class A1 or A2 according to EN 13501-1.

IV. International Standards and Quality Control: Ensuring Safety Throughout the Entire Process

The load-bearing safety of ceiling grids needs to be ensured throughout the entire cycle of design, material selection, construction, and maintenance.

1. Design Stage: BIM Modeling and Load Calculation

By using Building Information Modeling (BIM) technology to simulate the stress conditions of ceilings, the spacing of runners (usually 900 - 1200 mm) and the density of hanger rods (at least one per square meter) can be optimized. In a project at a super high-rise office building, BIM collaborative design was adopted, reducing material waste while improving structural safety.

2. Construction Stage: Key Node Control

· Hanger Rod Installation: Use expansion bolts for fixation, with a spacing error not exceeding 5 mm;

· Runner Connection: Adopt snap-in or bolt connections to avoid stress concentration caused by welding;

· Equipment Reinforcement: Heavy lighting fixtures should be connected to the building structure through independent steel frames rather than being directly suspended from the ceiling.

3. Maintenance Stage: Regular Inspections and Replacements

It is recommended to conduct load tests on ceilings every five years, focusing on issues such as hanger rod rusting, runner deformation, and loose connections. In the ceiling system of an international airport, Internet of Things (IoT) sensors are used to monitor structural stress in real-time, enabling preventive maintenance.

International Research Case:Research conducted by the University of Tokyo in Japan shows that regular maintenance can extend the service life of ceiling systems to more than 30 years while reducing safety risks by 30%.

Conclusion: Technological Innovation Drives the Upgrade of Ceiling Safety

The load-bearing design of ceiling grids is an important line of defense for building safety. By introducing triangular stable structures, light steel framing materials, and multi-functional integration technologies, modern ceiling systems have achieved a perfect balance between load-bearing, ventilation, sound insulation, and decoration. As a professional manufacturer of ceiling grids, we are committed to technological innovation and quality improvement, providing safer and more reliable ceiling solutions for customers worldwide and jointly promoting the sustainable development of the construction industry.

References

· Steel Construction Research: An academic journal focused on structural steel materials, offering insights into the properties and applications of light steel in ceiling grid production.

· Journal of Building Engineering (Elsevier): Covers building envelope systems, ceiling structure optimization, and material performance—supporting performance upgrades in ceiling applications.

· Construction and Building Materials (Elsevier): A leading international journal publishing research on advanced construction materials, including lightweight steel and composite ceiling structures.

· ASTM International: Provides global testing and performance standards for materials used in suspended ceiling systems and light-gauge steel construction.

· CEN (European Committee for Standardization): Offers harmonized European standards related to construction materials, ceiling systems, and metal framing components.

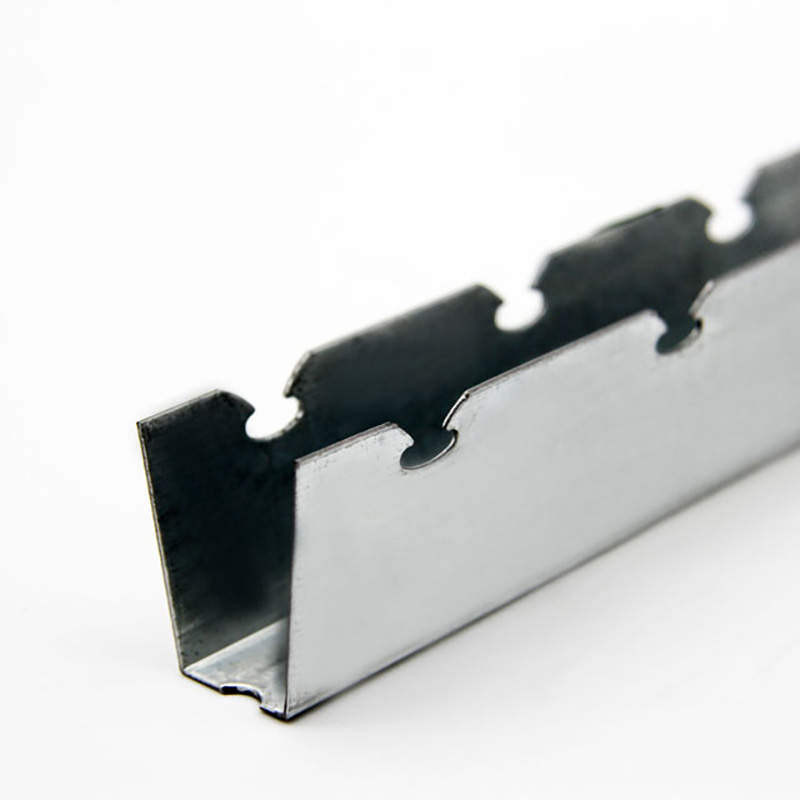

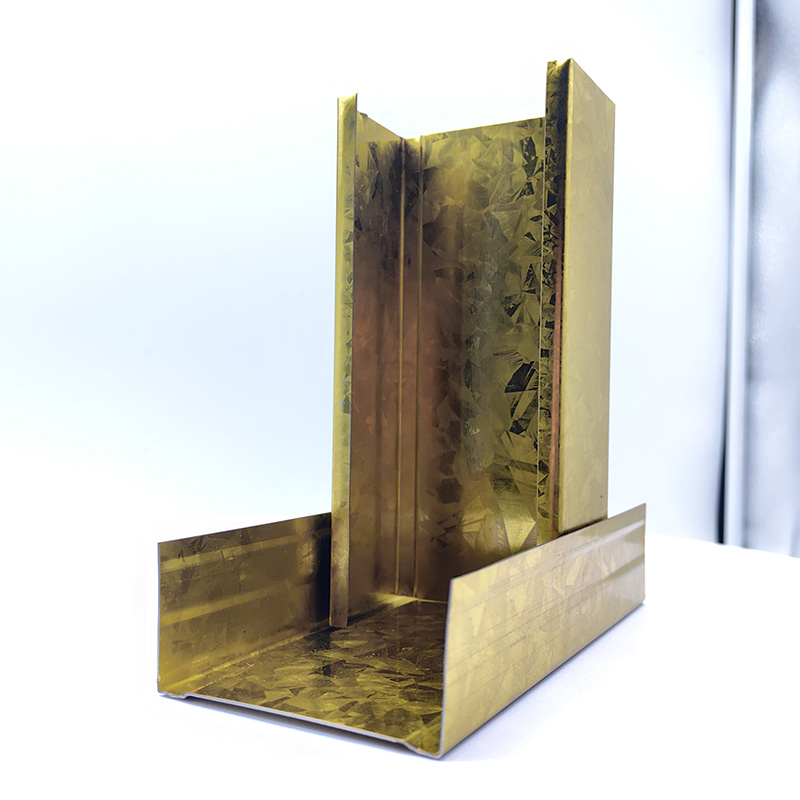

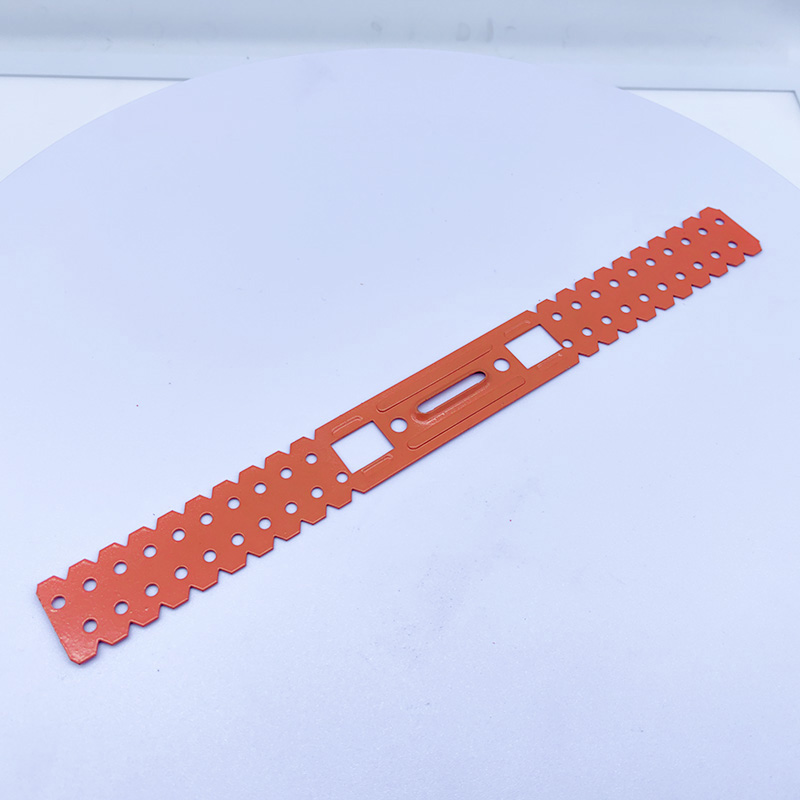

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

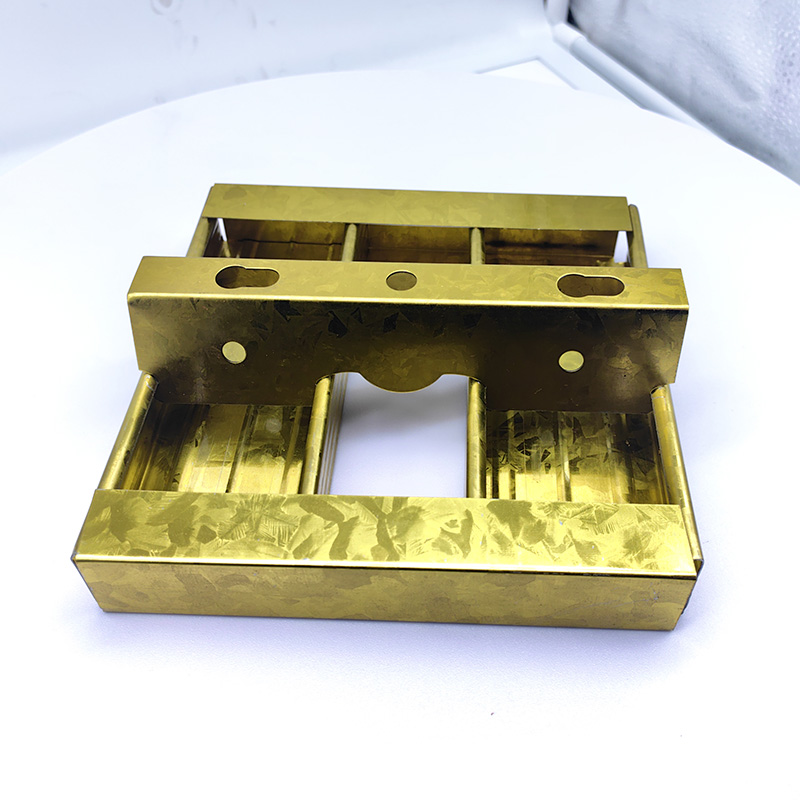

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

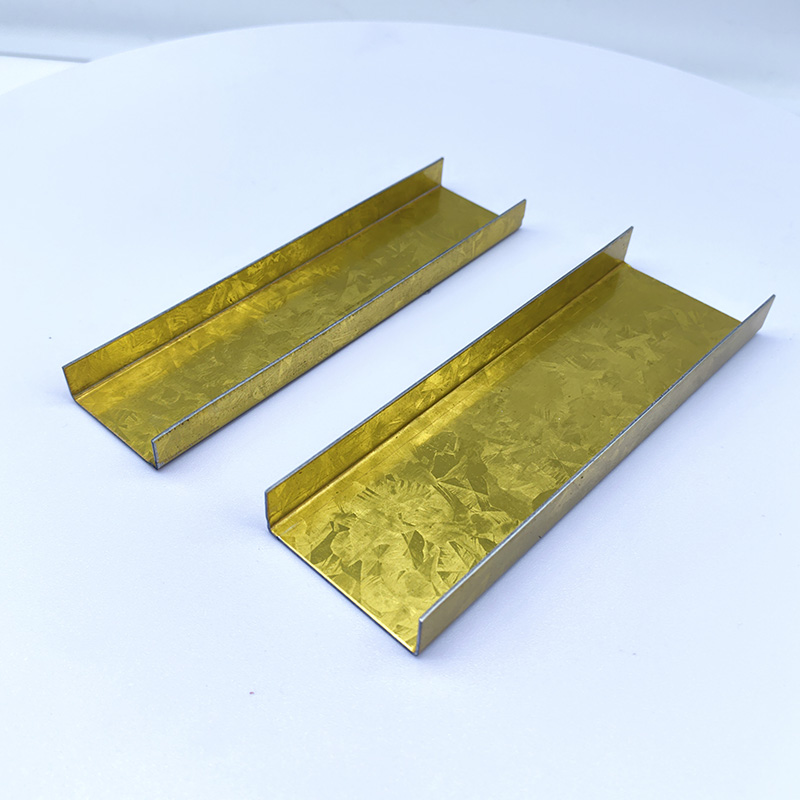

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...