What Are Metal Wall Corner Guards? An In-depth Analysis of Their Three Core Functions: Impact Resistance, Wear Resistance, and Aesthetics

2025-05-15 16:50:55

In home renovation and public space maintenance, wall corners are prone to damage due to frequent collisions and friction. Metal wall corner guards, thanks to their unique physical properties, have become an ideal choice for protecting wall corners and enhancing the quality of spaces. This article delves into the advantages of metal wall corner guards from the perspectives of their three core functions: impact resistance, wear resistance, and aesthetics. It also shares tips on selection and installation to help you choose the right corner protection solution for your home or venue.

I. Core Function Analysis: Unique Advantages of Metal Corner Guards

1.1 Impact Resistance: High Strength to Withstand External Forces

The high density and rigidity of metal materials endow wall corner guards with excellent impact resistance. Whether it's the high hardness of stainless steel or the toughness of aluminum alloy, both can effectively disperse impact forces, preventing dents and cracks in wall corners caused by collisions. Compared to plastic or PVC materials, metal corner guards are less likely to deform or shatter when subjected to heavy impacts or frequent friction, providing long-term and stable protection for wall corners, especially in high-traffic corridors, children's play areas, and other collision-prone zones.

1.2 Wear Resistance: A Guarantee of Lasting Durability

The wear resistance of metal far exceeds that of most non-metal materials. Scratches from daily cleaning and friction from moving furniture are unlikely to cause significant damage to the surface of metal corner guards. Meanwhile, metals possess good corrosion resistance. Through surface treatment processes (such as baking paint or oxidation treatment), their rust and fade resistance can be further enhanced, allowing them to maintain structural integrity and a like-new appearance even when exposed to humid environments or cleaning agents for extended periods. This significantly reduces replacement frequency and maintenance costs.

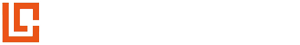

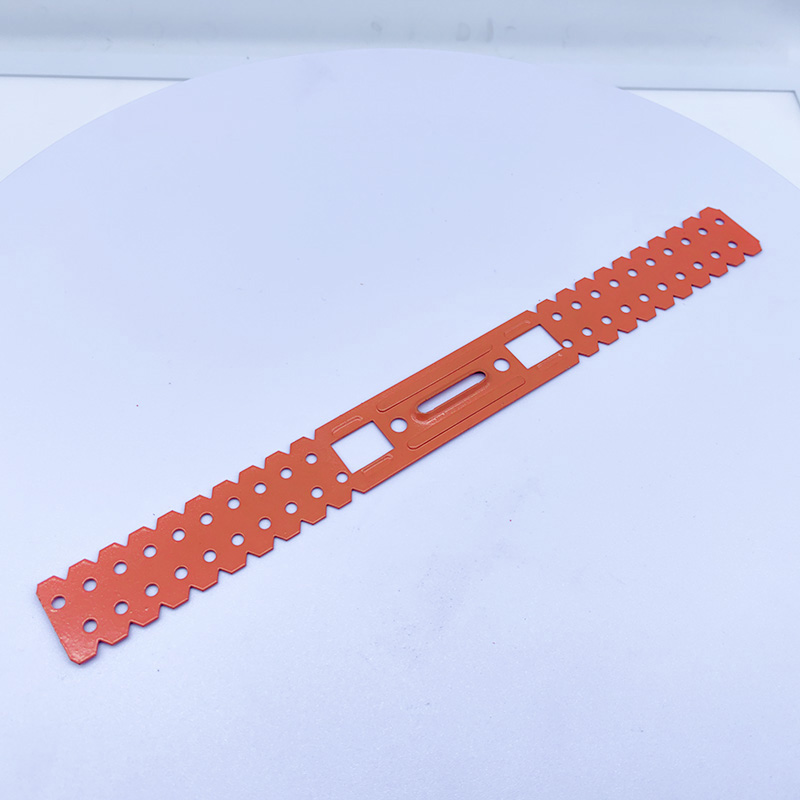

1.3 Aesthetic Compatibility: Enhancing the Design Texture of Spaces

Metal corner guards are not only practical but can also serve as the crowning touch in space decoration. Their surfaces can be processed to exhibit a variety of styles: matte silver complements modern minimalist styles, offering an understated yet technologically advanced feel; metal corner guards with a bronze-like or wood-grain texture can seamlessly blend into Chinese or retro-style spaces, imbuing them with a classical charm. In addition, metal corner guards feature smooth lines and a simple shape, integrating seamlessly with walls. They can protect wall corners without disrupting the overall visual harmony, achieving a harmonious blend of functionality and aesthetics.

II. Extended Performance: Environmental Friendliness, Safety, and Detail Design

2.1 Environmental and Safety Considerations

High-quality metal wall corner guards are crafted from environmentally friendly materials, with no harmful chemicals added during the manufacturing process, adhering to home health standards. Their surfaces are passivated or coated, free of sharp burrs, thereby reducing the risk of accidental scratches. Models with rounded or curved designs can further prevent injuries to children and pets in the event of a collision, balancing safety and health needs.

2.2 Installation Convenience

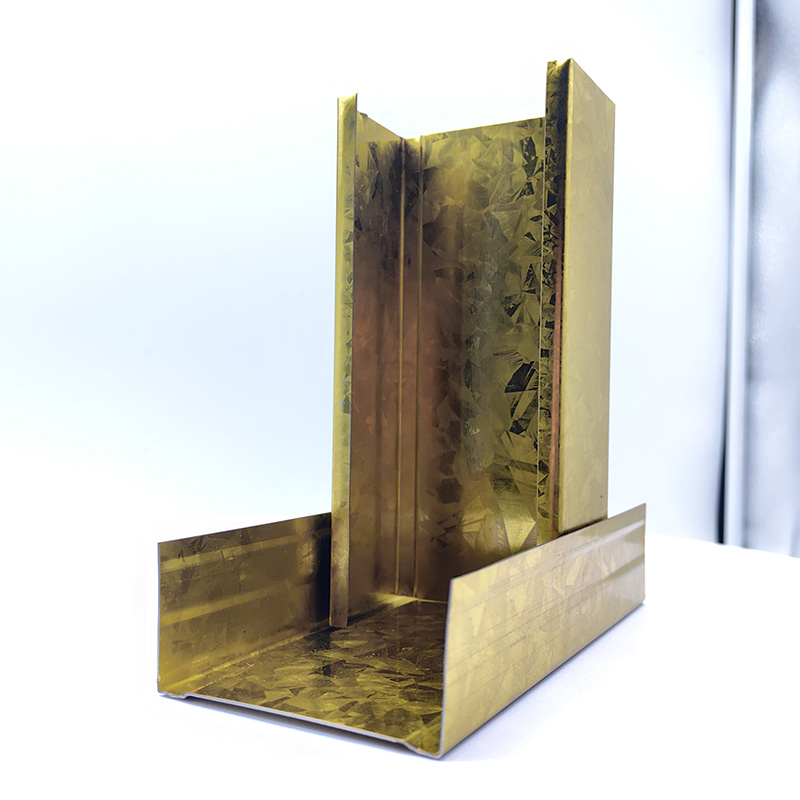

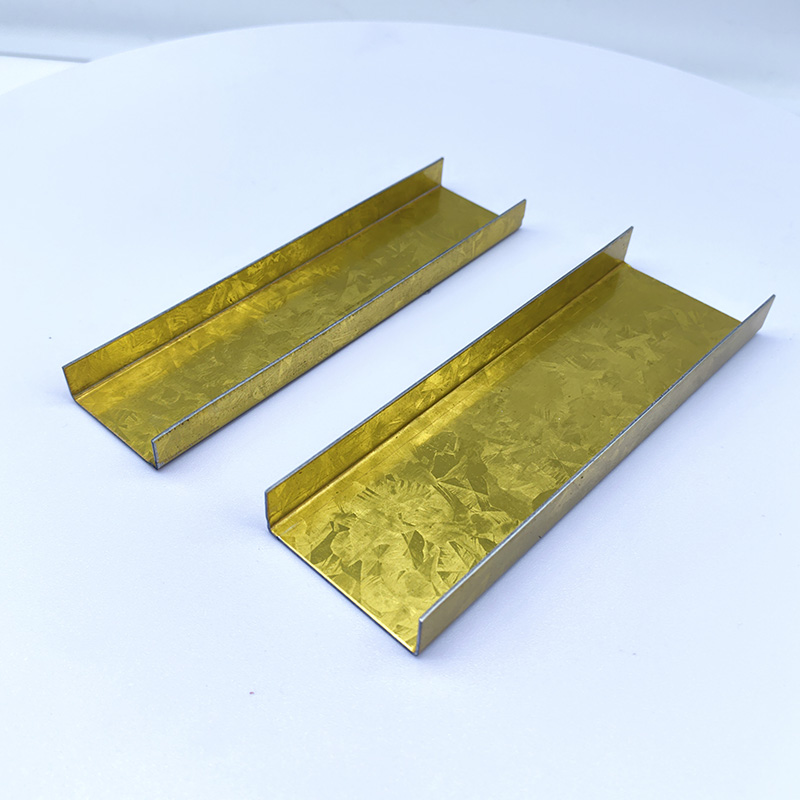

Metal corner guards are usually designed in L-shaped or U-shaped forms to fit the curvature of wall corners, with flexible installation methods. They can be easily adhered with special glue, causing no damage to walls, or fixed with expansion screws or nails for places with high load-bearing requirements. The installation process requires no complex tools or professional skills, allowing ordinary users to complete it effortlessly, saving time and labor costs.

III. Selection Tips: Matching Specifications and Scenarios

3.1 Material and Thickness Selection

Choose materials based on the usage scenario: stainless steel corner guards are suitable for humid and highly corrosive environments (such as kitchens and bathrooms); aluminum alloy corner guards are lightweight and cost-effective, commonly used for daily household protection. In terms of thickness, a moderate thickness is sufficient for regular usage scenarios. If strong impact resistance is needed, thicker models can be selected, but it's necessary to balance aesthetics and cost.

3.2 Specification Parameter Matching

Length: Choose the corresponding length based on the height of the wall corner. For whole-wall protection, prefer long-specification models to reduce splicing; for partial repairs, short-length models can be cut for use.

Width: Narrow corner guards (2-3 cm wide) are inconspicuous and suitable for spaces pursuing a minimalist style; wide models (over 5 cm wide) offer a larger protective area and stronger decorative effects, serving as visual focal points in spaces.

IV. Installation Guide: Ensuring Stability and Durability

4.1 Preparation of Installation Tools

Prepare tools such as a tape measure (for measuring length), a cutting machine or scissors (for cutting corner guards), a level (for calibrating verticality), special glue or nails (for fixing corner guards), and a rag (for cleaning walls).

4.2 Installation Steps and Precautions

Wall Cleaning: Thoroughly remove dust and oil stains from wall corners with a rag to ensure a dry and smooth surface, enhancing adhesion.

Measurement and Cutting: Accurately measure the length of the wall corner, leave a small margin, and cut the corner guard. The cut should be flat and free of burrs.

Fixed Installation: When adhering with glue, evenly apply glue to the back of the corner guard, slowly press it from top to bottom, and hold it in place. For nail fixing, mark the drilling positions in advance to avoid damaging pipelines inside the wall.

Calibration and Adjustment: Use a level to check the verticality of the corner guard and adjust it promptly to ensure straight lines, avoiding skewing that could affect protection and aesthetics.

V. Summary: Selecting According to Needs, Balancing Practicality and Aesthetics

Metal wall corner guards, with their core functions of impact resistance, wear resistance, and aesthetics, have become the preferred solution for modern space protection. When selecting, it's necessary to comprehensively consider factors such as the usage scenario, decor style, and budget to choose the appropriate material, specifications, and installation method. Through reasonable selection and standardized installation, metal corner guards can not only effectively protect wall corners and extend the service life of walls but also add design texture to spaces, achieving a dual enhancement of practical and aesthetic values.

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...