What is a Lightweight Steel Partition Wall? An In-depth Guide to Material Properties, Advantages and Disadvantages, and Applications

2025-05-15 17:27:16

I. Core Definition and Composition of Lightweight Steel Partition Walls

A lightweight steel partition wall is a lightweight wall structure composed of hot-dip galvanized lightweight steel keels as the framework, paired with various panel materials (such as gypsum board, cement fiberboard, etc.). It is a key component of prefabricated building systems. Its core components include:

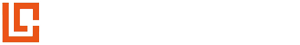

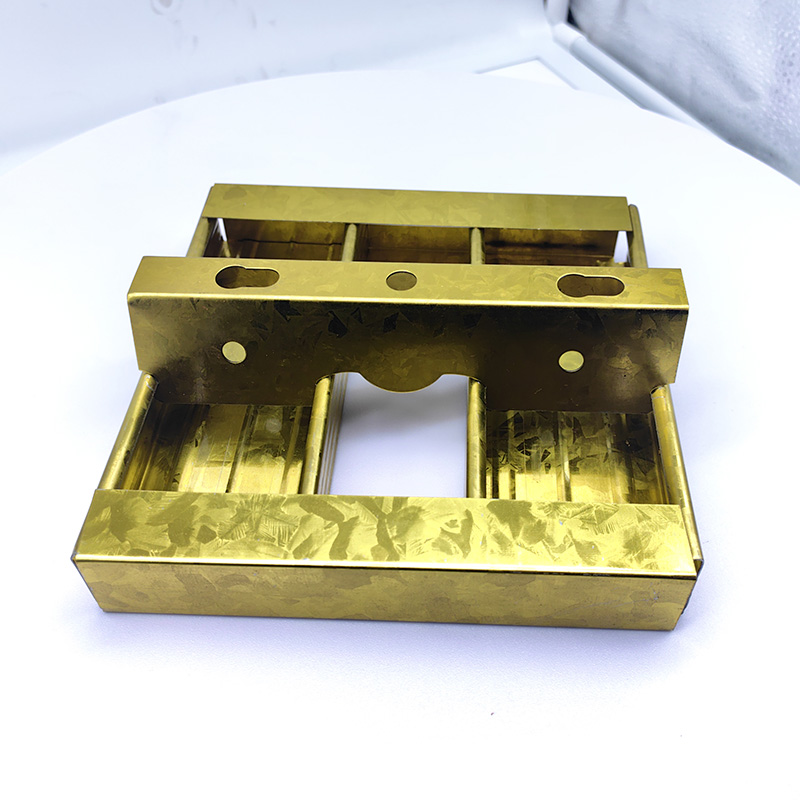

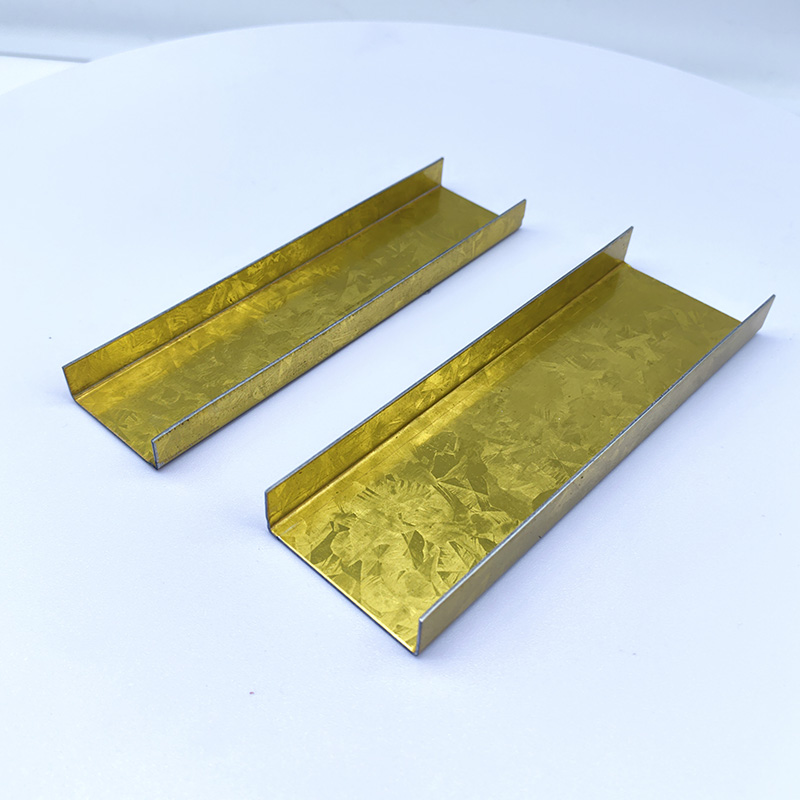

Lightweight Steel Keel Framework: Constructed from metal profiles, including ceiling tracks, floor tracks, and vertical studs, this framework provides structural support. Typically made from galvanized steel sheet, it offers high strength and corrosion resistance.

Panel Materials: Commonly used panels include gypsum board (for fire resistance and sound insulation), cement fiberboard (for moisture resistance and waterproofing), and calcium silicate board (for superior fire resistance). The choice of panel depends on functional requirements.

Filling Materials (Optional): Materials such as rock wool or glass wool can be filled into the keel cavities to enhance sound insulation, thermal insulation, or fire resistance.

II. Material Properties of Lightweight Steel Partition Walls

Lightweight

The overall weight is only 1/5 to 1/10 of that of traditional brick walls, significantly reducing the load on the main building structure. This makes it particularly suitable for high-rise buildings and renovation projects of old buildings.

Efficient Construction

Adopting modular dry construction methods, it eliminates the need for time-consuming processes such as bricklaying and plastering. The construction period is reduced by over 50% compared to traditional walls, making it ideal for rapid construction needs.

Flexible Design

Adjustable Thickness: Common thicknesses range from 75mm to 150mm, saving indoor space and increasing the usable floor area.

Diverse Shapes: It can incorporate curved or angular designs to meet personalized decoration styles.

Versatile Performance

Fire Resistance: Through panel combinations, it can achieve a fire resistance rating of 1-3 hours, meeting fire safety regulations.

Sound Insulation: The wall can achieve a sound insulation level of 30-50dB, suitable for spaces requiring a quiet environment.

Earthquake Resistance: The flexible connection structure can withstand earthquakes of magnitude 8 or above, enhancing building safety.

III. Advantages and Disadvantages of Lightweight Steel Partition Walls

Advantages:

High Space Utilization: The thin wall thickness increases the usable area.

Environmental and Energy Efficiency: Materials are recyclable, and construction pollution is minimal. The addition of thermal insulation materials significantly enhances energy efficiency.

Easy Disassembly: The modular structure facilitates renovation or reuse, making it suitable for temporary or leased spaces.

Disadvantages:

Limited Load-Bearing Capacity: Not suitable for load-bearing walls or heavy hanging objects (requires additional reinforcement).

Special Moisture-Proof Treatment Required: In humid areas (such as bathrooms), it needs to be paired with waterproof panels and moisture-proof processes.

High Precision in Construction Required: Uneven installation of keels may lead to panel cracking.

IV. Suitable Applications for Lightweight Steel Partition Walls

Residential Buildings

Used to separate spaces such as living rooms, bedrooms, and studies, especially suitable for optimizing layouts in small apartments. It can also serve as partition walls between households to meet sound insulation and fire resistance requirements, enhancing living comfort.

Commercial and Office Spaces

Suitable for quickly dividing open-plan office areas in office buildings, supporting flexible adjustments in the future. Hotel guest rooms can be constructed in a short period with standardized batch installation, reducing decoration costs.

Public Buildings

Meets the fire resistance and earthquake resistance requirements of schools, hospitals, and other places, and facilitates the concealment and maintenance of pipelines. Temporary buildings such as exhibition halls and pop-up stores can choose detachable and reusable lightweight steel partition walls.

Special Environments

In renovation projects of old buildings, there is no need to demolish the original walls. Lightweight steel partition walls can be directly installed, reducing construction disturbances. In loft mezzanines, their lightweight nature reduces the load on floor slabs, making them suitable for constructing duplex structures.

V. Key Points for Selection and Construction of Lightweight Steel Partition Walls

Material Selection:

Keels: Prioritize hot-dip galvanized keels with a wall thickness of ≥1.0mm for better corrosion resistance.

Panels: Choose gypsum board for dry environments, cement fiberboard for humid areas, and calcium silicate board for high fire resistance requirements.

Construction Precautions:

Base Treatment: Ensure the wall surface is flat with an error not exceeding 3mm to avoid skewed keel installation.

Pipeline Embedding: Plan water and electricity lines in advance to avoid damaging the wall structure by later chiseling.

Moisture-Proof Treatment: In areas such as bathrooms, a concrete guide wall or waterproof membrane should be set at the bottom, and panel joints should be sealed with waterproof materials.

Acceptance Criteria:

Flatness: Check with a 2m straightedge, with an error ≤3mm.

Perpendicularity: Check with a verticality detector, with an error ≤2mm.

Joint Treatment: Panel joints should have a 3-5mm gap, filled with joint compound and pasted with anti-crack paper tape.

VI. Comparison Between Lightweight Steel Partition Walls and Traditional Walls

The construction period of lightweight steel partition walls is only 1/5 to 1/3 of that of traditional brick walls (such as 240mm brick walls), with lower overall costs and multifunctional integration advantages (fire resistance, sound insulation, earthquake resistance). Traditional brick walls have complex construction processes, generate more construction waste, and have poor sustainability. In contrast, lightweight steel partition walls have a recyclable material content of ≥80%, making them more in line with the trend of green buildings.

VII. Conclusion

Lightweight steel partition walls have become a mainstream choice to replace traditional walls in modern architecture due to their lightweight nature, efficient construction, and versatile functions. Whether in residential, commercial, or public spaces, they excel in optimizing space utilization and enhancing building performance. When selecting, it is essential to consider the usage scenario, budget, and design requirements to choose appropriate materials and construction plans, fully leveraging the comprehensive advantages of lightweight steel partition walls to create more flexible, safe, and environmentally friendly living and working environments.

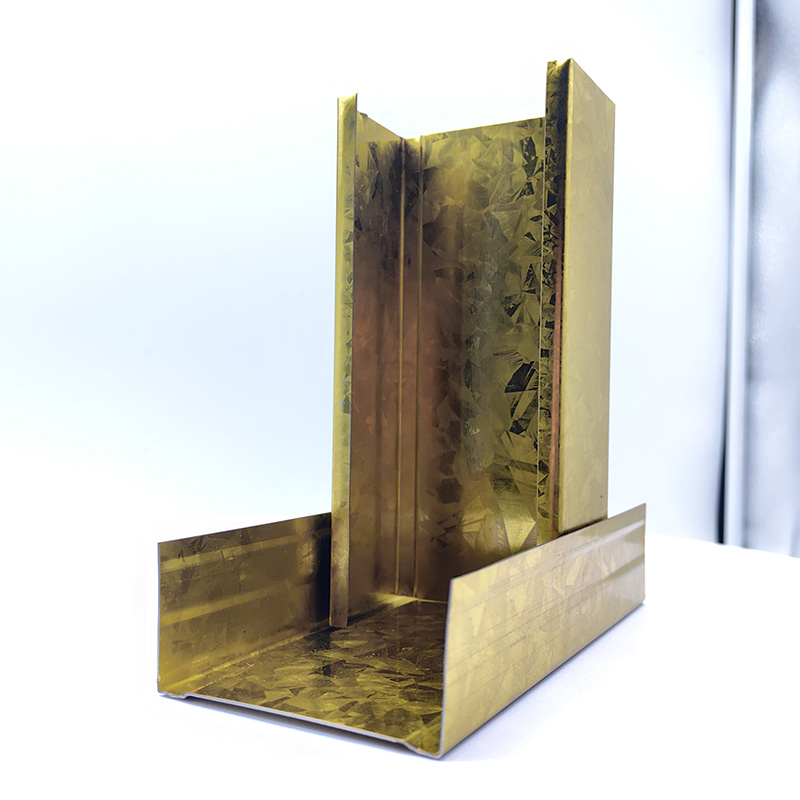

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...