Precision Tools for Corner Wall Angle Installation: A Must-Have List for Contractors & DIYers

2025-06-11 15:54:22

I. Introduction: The Foundation of Precision Measurement in Construction

In the fields of architectural decoration and home renovation, the precise installation of corner and wall angles is a pivotal factor determining the quality of a project. Whether it's creating an aesthetically pleasing and harmonious indoor space or ensuring the structural stability of a building, accurate angle control is indispensable. For contractors, precise angle installation enhances project delivery quality and builds customer trust. For DIY enthusiasts, mastering precise measurement and installation skills allows for home renovations that better meet expectations. This article will delve into the essential tools for corner and wall angle installation and their usage tips, providing practical guidance for various types of constructors.

II. The Importance of Precise Corner and Wall Angle Installation

2.1 Stringent Requirements in Different Construction Scenarios

In interior decoration, if there is a significant error in the corner angle during cabinet installation, the cabinet body may not fit snugly against the wall, leading to issues such as unsightly gaps, dust accumulation, and unstable item placement. For skirting board installation, precise wall angles are crucial; otherwise, the skirting board will not seamlessly connect with the wall, disrupting the overall visual effect. In the construction sector, the precision of wall-building angles is vital for the overall structural stability of a building. If there is an angular deviation in door and window installation, it can result in poor opening and closing, reduced sealing performance, and compromised thermal insulation properties of the building.

2.2 Construction Hazards Caused by Angular Deviations

Errors in angle measurement and installation first and foremost significantly degrade the decoration effect, such as causing skewed decorative lines on walls and an unbalanced spatial layout. Secondly, these errors lead to the waste of construction materials. For example, incorrect board cutting due to inaccurate angles may necessitate re-purchasing materials. Additionally, angular deviations pose difficulties for subsequent installation work, increasing construction costs and time, and may even pose safety hazards.

III. Detailed Explanation of Essential Tools for Corner and Wall Angle Installation

3.1 Traditional Practical Measuring Tools

3.1.1 Protractor

A protractor is a basic angle-measuring tool, mainly divided into semi-circular and full-circular protractors. Semi-circular protractors typically have a scale range of 0° - 180°, while full-circular protractors can measure angles from 0° - 360°. Their measurement principle is based on the geometric division of angles. By aligning the center of the protractor with the corner vertex and the zero-degree line with the wall baseline, the corresponding scale value on the other side can be read to determine the wall angle. Protractors are suitable for simple angle measurement scenarios, such as small-scale angle checks in interior decoration, but have limitations when measuring complex corners or long-distance angles.

3.1.2 Combination Square

A combination square consists of a ruler and an adjustable arm. By adjusting the angle between the arm and the ruler, it can perform angle measurement and right-angle verification functions. During use, one side of the ruler is placed flush against the wall, and the arm is adjusted to fit the other wall. The angle can then be determined by reading the scale. In measuring complex corners, the combination square can flexibly adapt to different wall shapes, quickly and accurately obtaining angle data, making it a valuable tool for handling irregular corner angle installations.

3.2 Modern Intelligent Measuring Tools

3.2.1 Digital Angle Gauge

A digital angle gauge employs sensor technology to convert angle measurement data into digital signals and display them directly on the screen. It features high-precision measurement capabilities, enabling quick and accurate acquisition of corner and wall angle data. Some digital angle gauges also support data storage functions, allowing constructors to conveniently view historical measurement data. Compared to traditional measuring tools, digital angle gauges offer higher measurement efficiency and smaller errors, making them particularly suitable for construction scenarios with extremely high measurement accuracy requirements.

3.2.2 Laser Angle Measurer

A laser angle measurer utilizes laser projection principles to determine angles by emitting laser beams and capturing reflected signals. Its advantages include the ability to perform long-distance and multi-point measurements. In large-scale construction projects, it can quickly complete angle measurements for large wall areas or complex building structures, significantly improving construction efficiency and reducing the tedium and errors associated with manual measurements.

IV. Tool Selection and Usage Tips

4.1 Selecting the Right Tool Based on Needs

For small-scale DIY home renovation projects, such as simple bookshelf installations or decorative line placements, a protractor and combination square can meet basic angle measurement needs, offering simplicity of operation and low cost. For large-scale construction projects undertaken by professional contractors, which involve complex building structures and high-precision installation requirements, digital angle gauges and laser angle measurers are more suitable, ensuring construction efficiency and precise angle installation.

4.2 Methods to Enhance Measurement and Installation Accuracy

Before measuring corner and wall angles, it is essential to clean the walls, removing dust, stains, and other debris to ensure a flat and clean measurement reference surface. Additionally, reasonably determining the measurement reference line, possibly with the aid of a level, can guarantee the accuracy of the reference line. When using measuring tools, regular calibration should be performed to maintain measurement accuracy. During the measurement process, taking multiple measurements and averaging the results can effectively reduce inaccuracies caused by random errors. During installation, fine adjustments should be made based on measurement data to ensure precise angle installation.

V. Common Problems and Solutions

5.1 Challenges in Measurement and Installation

In actual construction, measuring angles on irregular walls is a significant challenge. Uneven or oddly shaped walls can interfere with the normal use of measuring tools, leading to inaccurate measurement data. Furthermore, operating in confined spaces restricts the use of measuring tools, increasing the difficulty of measurement and installation.

5.2 Effective Solutions

For irregular walls, special auxiliary tools such as flexible measuring tapes that can bend to fit the wall shape can be used for measurement. Alternatively, a segmented measurement and calculation method can be employed to obtain accurate angle data. When working in confined spaces, choosing compact and portable measuring tools, such as small digital angle gauges, and reasonably planning the operation sequence and standing position can improve the feasibility of measurement and installation.

VI. Future Trends in Tool Development

6.1 Directions for Technological Innovation

In the future, corner and wall angle measurement and installation tools will move towards intelligence. By connecting with mobile apps, they will enable real-time sharing, analysis, and cloud storage of measurement data, facilitating remote collaboration and data management for constructors. Additionally, tool functions will be further integrated, combining angle measurement, distance measurement, level detection, and other functions into one device to meet the diverse measurement needs of constructors and improve work efficiency.

6.2 Impact on Constructors

The trend towards intelligent and multifunctional tools will significantly enhance the construction efficiency and project quality for both contractors and DIY enthusiasts. Constructors will no longer need to frequently switch between different tools, simplifying the operation process. Meanwhile, with the help of intelligent analysis functions, they can more precisely control construction details. However, constructors will also need to continuously learn how to use new tools. Although the initial learning cost may increase, in the long run, the operational threshold will gradually decrease due to the user-friendly design of the tools.

VII. Conclusion: Harnessing Tools for Quality Construction

Precise installation of corner and wall angles hinges on appropriate measuring tools and correct usage methods. From traditional protractors and combination squares to modern digital angle gauges and laser angle measurers, different tools have their own advantages and suitable scenarios. Contractors and DIY enthusiasts should select the appropriate tools based on their construction needs and master practical measurement and installation techniques. With the continuous innovation and development of measuring tools, precise construction will become more efficient and convenient. We look forward to constructors harnessing these essential tools to create more high-quality construction projects and explore more skills and joys in measurement and installation.

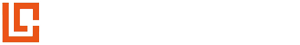

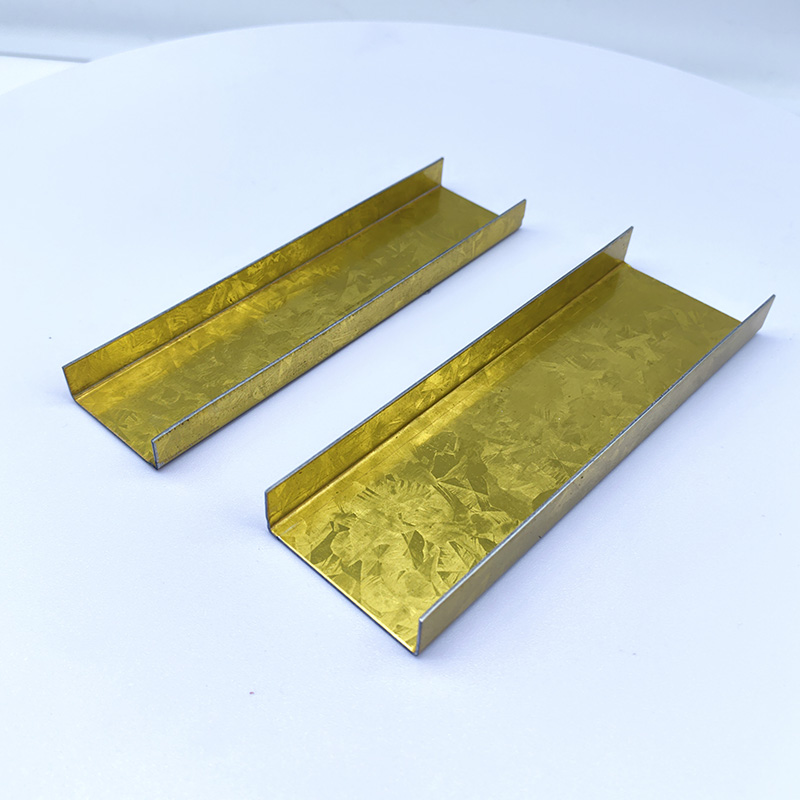

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

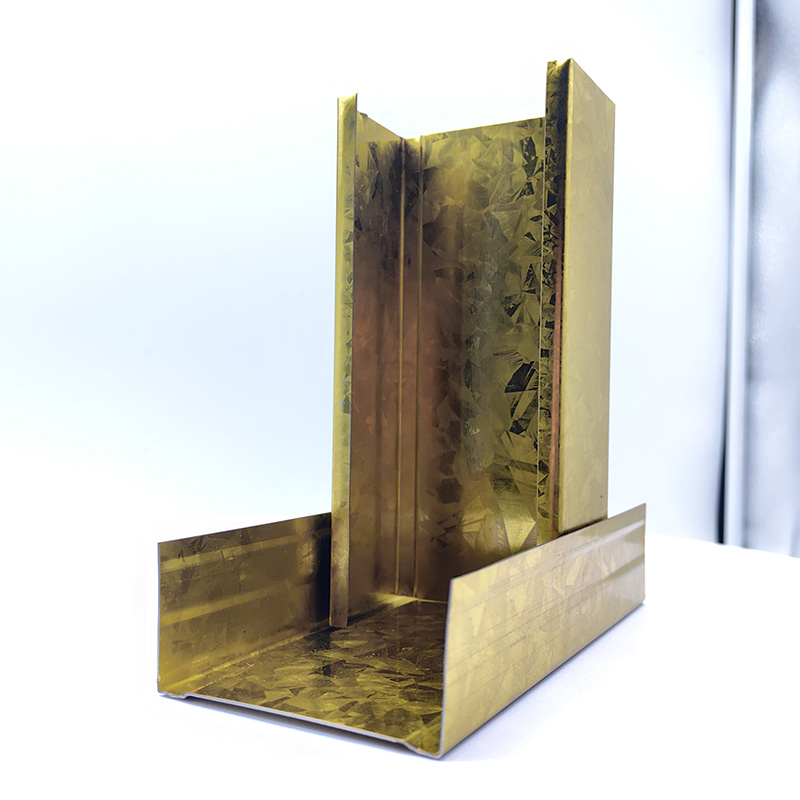

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

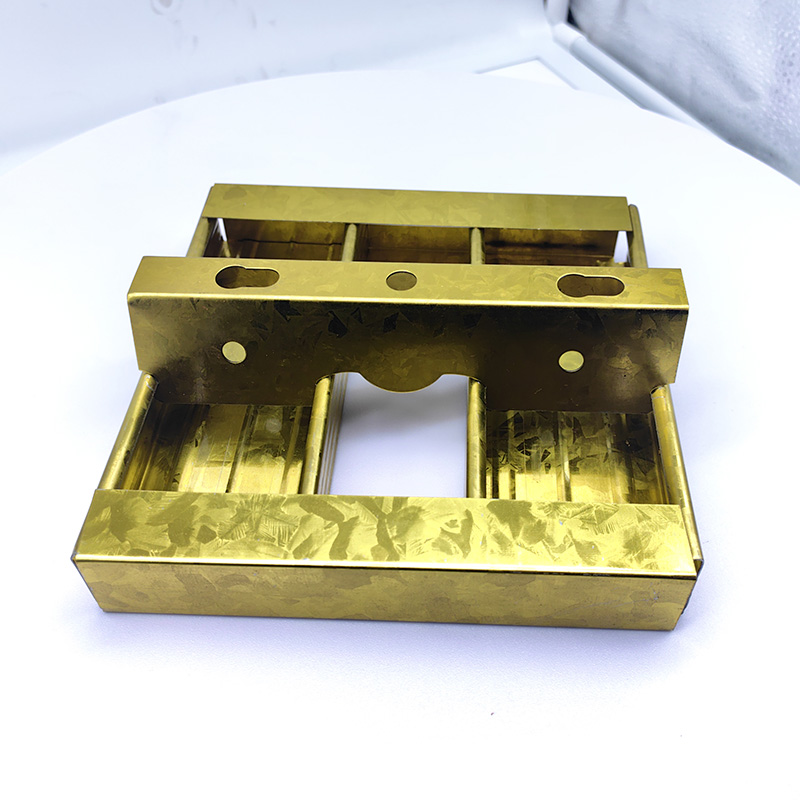

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...