Fixing Uneven Corners: Step - by - Step Alignment Techniques with Corner Wall Angles

2025-06-14 18:41:49

I. Introduction: Confronting the Pain Points in Decoration and Starting a Journey of Precise Repair

In the field of architectural decoration, uneven wall corners are a common issue that plagues many builders and homeowners. Whether it's a new - house decoration or an old - house renovation, irregular wall corners not only ruin the overall aesthetic appeal of the space but may also affect the smooth progress of subsequent projects such as furniture installation and decorative trim laying. Precisely repairing uneven wall corners is a crucial step in enhancing the quality of decoration and ensuring structural stability. This article will provide you with a comprehensive and practical solution through a systematic step - by - step approach combined with corner wall angle alignment methods.

II. Uneven Wall Corners: Analysis of Causes and Interpretation of Impacts

2.1 Exploring the Root Causes

The emergence of uneven wall corners often stems from mistakes in multiple stages. During the construction phase, measurement errors and inaccurate template installation can lead to deviations in wall angles. Over time, ground settlement and wall deformation caused by changes in environmental temperature and humidity can gradually make wall corners irregular. In addition, rough construction and improper base treatment during the decoration process are also significant factors contributing to uneven wall corners.

2.2 Manifestation of Negative Impacts

The impact of uneven wall corners on the decoration effect is obvious. Decorative trims cannot fit snugly against the wall corners, resulting in visible gaps and skewing. When placing furniture, the gaps between the furniture and the wall corners not only affect the aesthetics but also make it difficult to clean the accumulated dust. From a visual perspective, unbalanced wall corners disrupt the overall harmony and reduce the sense of quality in the decoration.

III. Tools and Materials Preparation: Essentials for a Successful Repair

3.1 Precision Measurement Tools

Digital angle finders, with their high - precision sensor technology, can quickly and accurately obtain corner angle data. They are easy to operate and suitable for various construction scenarios. Combination squares, with their flexible structures, play an important role in measuring complex corner angles and verifying right angles, making them indispensable basic measurement tools.

3.2 Construction Operation Tools

Grinding equipment such as electric grinders and sanding machines are used for grinding and leveling the wall surface. Leveling and filling tools, including scrapers and trowels, are used in conjunction with leveling materials to achieve a flat repair of the wall corners.

3.3 Auxiliary Repair Materials

Leveling putty should have good adhesion, ease of grinding, and filling properties to meet different degrees of repair needs. Wall corner protectors come in a variety of materials, such as plastic, metal, and PVC. When choosing, factors such as strength, corrosion resistance, and aesthetics need to be comprehensively considered.

IV. Step - by - Step Repair Techniques: A Full - Process Analysis from Measurement to Acceptance

4.1 Step One: Precise Measurement to Lay the Foundation for Repair

Multi - angle measurement is the key. Use a digital angle finder or a combination square to measure the internal and external corners of the wall multiple times. Record the angle data at different positions and analyze the deviation situation. At the same time, evaluate the severity of the problem based on the measurement results, distinguishing between minor deviations (e.g., small angle errors, local wall unevenness) and severe deformations (e.g., obvious skewing of wall corners, damage to the wall structure) to provide a basis for the subsequent repair plan.

4.2 Step Two: Base Treatment to Create Good Construction Conditions

First, clean the wall base to remove old decorative layers, dust, oil stains, and other debris, ensuring that the base surface is flat and clean. Before construction, take safety precautions, cover and protect the surrounding areas, and have construction personnel wear protective equipment to avoid injuries from dust and debris.

4.3 Step Three: Leveling and Reshaping the Wall Corners

For minor deviations, use leveling putty for coating and repair. Apply and compact it evenly with a scraper. After it dries, sand it flat with sandpaper. If the wall corners have severe deformations, consider partial demolition and reconstruction, strengthen the wall structure, and then carry out leveling treatment.

4.4 Step Four: Angle Alignment for Precise Installation

When installing corner protectors, for standard right - angled wall corners, use a level or a laser level to assist in calibration, ensuring that the corner protectors are vertical and horizontal. For wall corners with special angles, you can customize corner protectors with corresponding angles or achieve a precise fit by cutting and splicing ordinary corner protectors.

4.5 Step Five: Surface Treatment and Acceptance to Ensure Repair Quality

After completing the wall corner repair, carry out the construction of the decorative surface layer. Whether it's paint application or facing installation, pay attention to maintaining the surface flatness. During acceptance, re - check the flatness and angle accuracy of the wall corners from multiple angles to ensure that the errors are within a reasonable range and achieve the desired repair effect.

V. Efficient Repair: Mastering Tips and Precautions

5.1 Tailoring to Different Wall Materials: Key Points for Handling

Brick walls are strong, but during repair, attention should be paid to avoiding excessive grinding that may damage the wall. Gypsum board walls are relatively soft, and the force should be controlled during the leveling process to prevent board cracking. For new - type wall materials, appropriate repair materials and construction methods should be selected according to their characteristics.

5.2 Overall Control: Strategies for Optimizing Construction Period and Cost

Reasonably plan the construction process, link measurement, leveling, installation, and other stages in an orderly manner to avoid delays caused by disordered work procedures. Reduce material waste through precise measurement and reasonable cutting of materials, effectively controlling the repair cost.

5.3 Adapting to the Seasons: Key Points for Seasonal Construction

In seasons with high humidity, pay attention to the drying time of leveling materials to avoid a decline in construction quality due to difficulty in water evaporation. When the temperature is too low, the performance of some materials may be affected. Appropriate insulation measures should be taken or low - temperature suitable materials should be selected.

VI. Tackling Difficulties: Common Problems and Solutions

6.1 Typical Dilemmas in the Repair Process

After multiple leveling attempts, the wall surface is still uneven, which may be due to incomplete base treatment or uneven application of leveling materials. The corner angles keep deviating, which may be related to inaccurate measurement or loose installation of corner protectors.

6.2 Effective Solutions

For the problem of uneven wall surfaces after multiple leveling attempts, re - check the base to ensure that there are no protrusions or depressions, and apply the leveling materials strictly in accordance with construction specifications. If the corner angles keep deviating, re - measure and calibrate, strengthen the installation of corner protectors, and replace the installation method if necessary.

VII. Technological Frontier: Prospects for Future Repair Trends

7.1 Material Innovation: More Efficient and Intelligent Repair Options

Fast - curing leveling materials will shorten the construction period and improve repair efficiency. Smart - calibrating corner protectors may incorporate technologies such as automatic sensing and angle adjustment, making wall corner repair more precise and convenient.

7.2 Equipment Upgrades: The Era of Automation and Intelligence

Automated measurement and leveling equipment are expected to achieve one - button operation, automatically completing wall corner measurement and leveling work. The application of AR technology in wall corner repair can display the repair effect in real - time through virtual models, assisting builders in precise operations.

VIII. Conclusion: Mastering the Techniques to Achieve Perfect Wall Corners

Repairing uneven wall corners is no easy task, but through systematic step - by - step techniques, appropriate tools and materials, and practical repair tips, every builder and DIY enthusiast can achieve precise repairs. Every step, from measurement and evaluation to acceptance, is crucial. With the continuous development of technology, wall corner repair will become more efficient and intelligent in the future. I hope the content of this article can be of help to you, allowing you to create perfect wall corners and enhance the quality of your space during the decoration process.

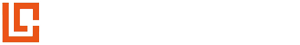

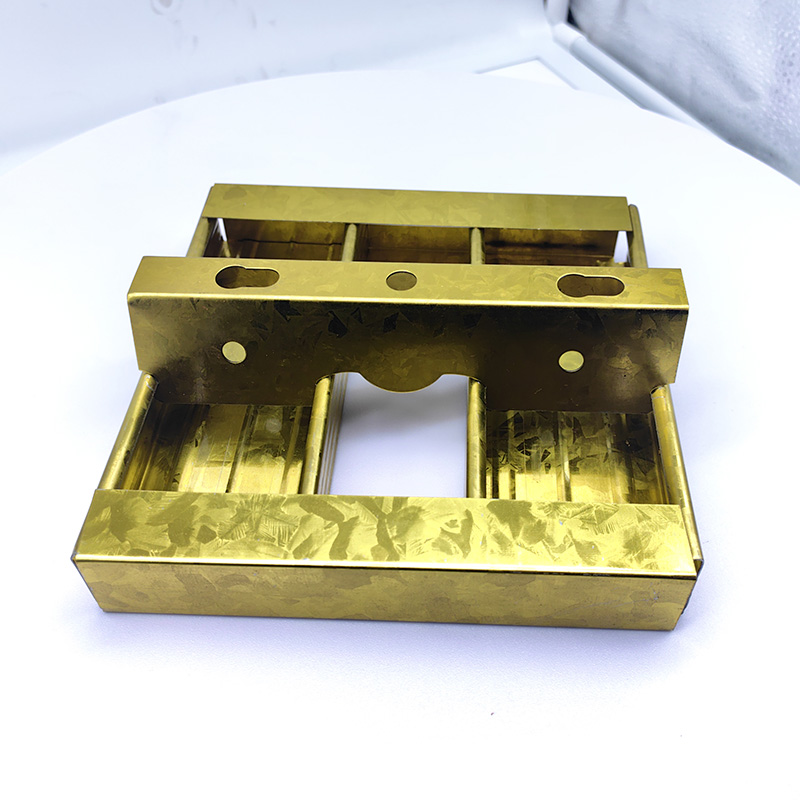

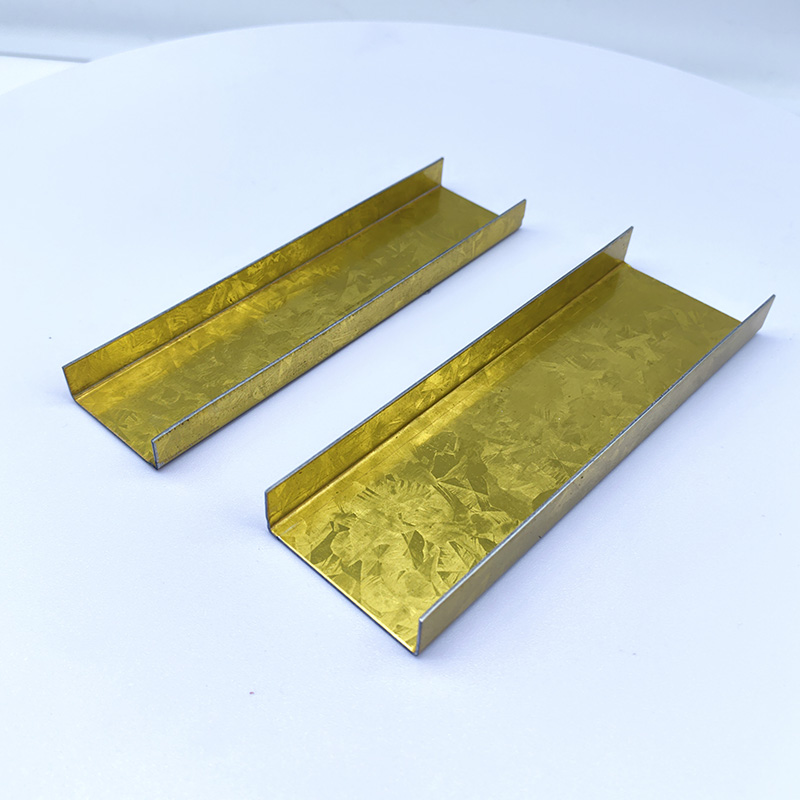

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

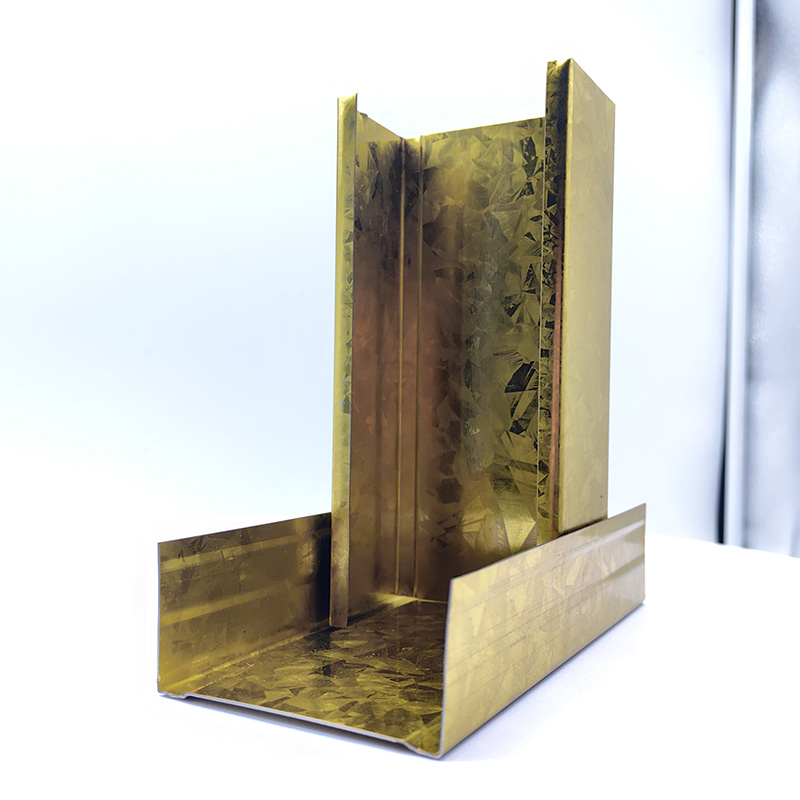

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...