Durability Meets Design: Choosing the Right Corner Wall Angle for High - Traffic Areas

2025-06-20 23:18:22

I. Introduction: The Dual Challenges of Corners in High - Traffic Zones

In architectural spaces, corners in high - traffic areas are constantly subjected to frequent collisions, frictions, and scratches over the long term. Problems such as wall surface damage and corner cracking are common occurrences. For these areas, the selection of corner guards should not only meet durability requirements to withstand daily high - intensity wear and tear but also possess a good sense of design that complements the overall space style. This article will delve into how to achieve a perfect balance between durability and design in high - traffic areas, providing comprehensive guidance for choosing the appropriate corner guards.

II. Analysis of the Special Needs of Corners in High - Traffic Areas

2.1 Characteristics and Risks of High - Traffic Areas

Corridors, stairwells, shopping mall aisles, and school corridors are areas with high pedestrian traffic. The frequent movement of furniture and the passage of carts make corners highly susceptible to physical impacts. Long - term friction and scratches can cause the wall coating to peel off and the corner structure to be damaged, not only affecting the aesthetic appeal of the space but also potentially threatening the stability of the wall structure.

2.2 Performance Requirements for Corner Guards

To meet these challenges, corner guards need to have high strength, impact resistance, and wear resistance, enabling them to withstand various external forces during daily use. In terms of design, they should harmonize with the space's decoration style. From color, shape to material texture, they need to be integrated into the overall design language to avoid disrupting the space's beauty due to an incongruous corner guard.

III. Interpretation of the Types and Characteristics of Corner Guards

3.1 Classification Based on Materials and Their Features

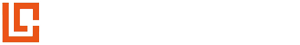

Metal Corner Guards: Corner guards made of stainless steel or aluminum alloy are highly strong and corrosion - resistant, offering excellent durability. Their metallic luster gives the space a modern feel. Through surface treatments, they can be customized with a variety of colors and textures to suit different design styles.

Plastic Corner Guards: PVC and ABS plastic corner guards have good flexibility, low cost, and are easy to install. Their rich color options allow them to simulate textures such as wood grain and stone, meeting diverse design needs, especially suitable for cost - sensitive projects.

Composite Material Corner Guards: Combining the advantages of multiple materials, they balance strength and toughness. While ensuring durability, they support a variety of shape designs, enabling personalized customization to meet the needs of high - end or special design scenarios.

3.2 Types of Corner Guards Classified by Function

Ordinary Protective Corner Guards: Their main function is basic protection, effectively resisting collisions and wear. They are suitable for public areas with low decorative requirements, such as warehouse and industrial plant corner protection.

Decorative Corner Guards: They focus on design elements. Through decorative details such as carvings and textures, they enhance the space's aesthetic appeal while providing protection. They are commonly used in residential and commercial display spaces where visual effects are highly valued.

IV. Key Considerations for Choosing Corner Guards

4.1 Evaluation of Durability

When selecting corner guards, it is necessary to consider the material's strength and impact resistance to ensure that they can withstand daily wear and tear in high - traffic areas. At the same time, wear resistance, corrosion resistance, and anti - aging performance are also crucial, as they directly relate to the service life and maintenance cost of the corner guards.

4.2 Analysis of Design Compatibility

Adapting to the space's decoration style is the core of design. Whether it is a modern minimalist, vintage European, or industrial style, the color, size, and surface treatment process of the corner guards should be harmoniously integrated with the overall environment, making them an organic part of the space design.

4.3 Balancing Practical Performance

The ease of installation affects construction efficiency, and the difficulty of maintenance and cleaning relates to the later - use cost. In addition, a cost - effectiveness analysis should be carried out in combination with the budget. On the premise of meeting durability and design requirements, choose cost - effective corner guards to maximize benefits.

V. Selection Strategies for Corner Guards in Different High - Traffic Areas

5.1 Residential High - Traffic Areas

In family corridors and staircase corners, corner guards that combine both protection and aesthetics can be selected. In children's activity areas, products with high safety and rounded edges should be given priority. At the same time, colorful and interestingly shaped corner guards can be chosen to add fun to the space.

5.2 Commercial High - Traffic Areas

In shopping mall aisles and store entrances, where there is a large pedestrian flow and a risk of cargo handling collisions, high - strength and impact - resistant corner guards are required. Office spaces pay more attention to the combination of simple design and durability. Products with clean lines and low - key colors should be selected to maintain a professional feel in the space.

5.3 High - Traffic Areas in Public Facilities

In places such as schools and hospitals, where high hygiene standards are required, antibacterial and easy - to - clean corner guards should be chosen. In transportation hub areas with a complex mix of people and frequent luggage dragging, high - strength and excellent impact - resistant corner guards should be used to ensure the long - term stability of the corners.

VI. Guidelines for Installation and Maintenance

6.1 Installation Methods and Techniques

Different materials of corner guards have different installation methods, with common ones being adhesion and nailing. During installation, it is necessary to ensure accurate angles and a tight fit with the corner. Tools such as spirit levels and right - angle squares can be used to assist in ensuring a flat and beautiful installation effect.

6.2 Daily Maintenance and Care

For daily cleaning, appropriate cleaning agents should be selected according to the material of the corner guards to avoid using highly corrosive chemicals. Regularly check the integrity of the corner guards. If any damage is found, repair or replace them in a timely manner to ensure their continuous protective function.

VII. Common Problems and Solutions

7.1 Summary of Common Problems

During the selection process, problems such as mismatched corner guard sizes with the corner and incoordination with the space style after installation may occur. During use, premature damage to the corner guards is also relatively common.

7.2 Targeted Solutions

By accurately measuring the corner size, choose a suitable corner guard model. Before installation, make a good design plan to ensure that the color and shape are consistent with the space style. For the problem of premature damage, regular maintenance and the selection of high - quality products can effectively extend the service life of the corner guards.

VIII. Prospects for Future Development Trends

8.1 Material Innovation Directions

In the future, new high - strength and environmentally friendly materials will continue to emerge. Smart materials, such as self - healing materials, may also be applied to corner guards, further enhancing their durability and functionality.

8.2 Design Innovation Trends

Personalized custom design will become the mainstream. At the same time, corner guards may be integrated with smart home systems and smart space design to achieve a deep combination of function and aesthetics.

IX. Conclusion: Creating Durable and Aesthetic Corners

Choosing corner guards in high - traffic areas is a comprehensive consideration of durability and design. From understanding regional needs, familiarizing oneself with the types and characteristics of corner guards, to mastering selection points and installation and maintenance methods, each link is crucial. Through reasonable selection and application, it can not only effectively protect the corners but also enhance the space quality. It is hoped that this article can provide practical references for readers in choosing corner guards for high - traffic areas, creating an ideal space that combines practicality and aesthetics.

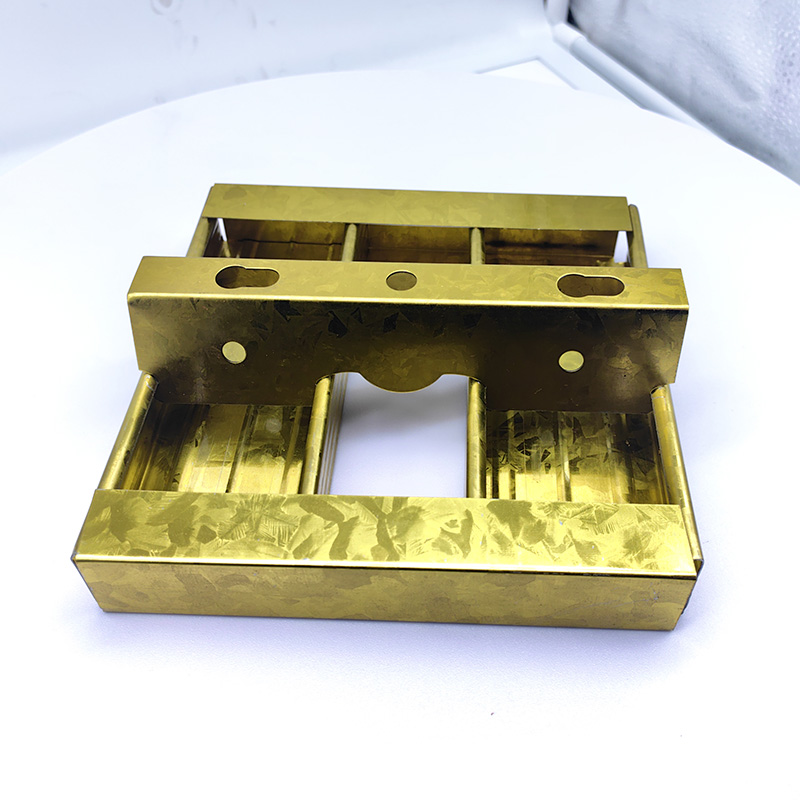

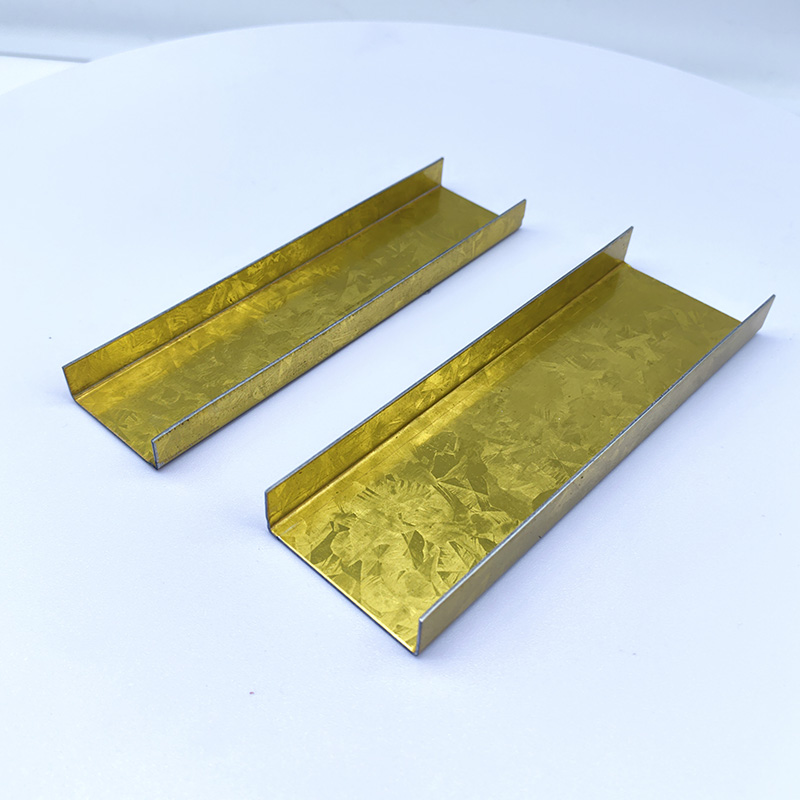

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

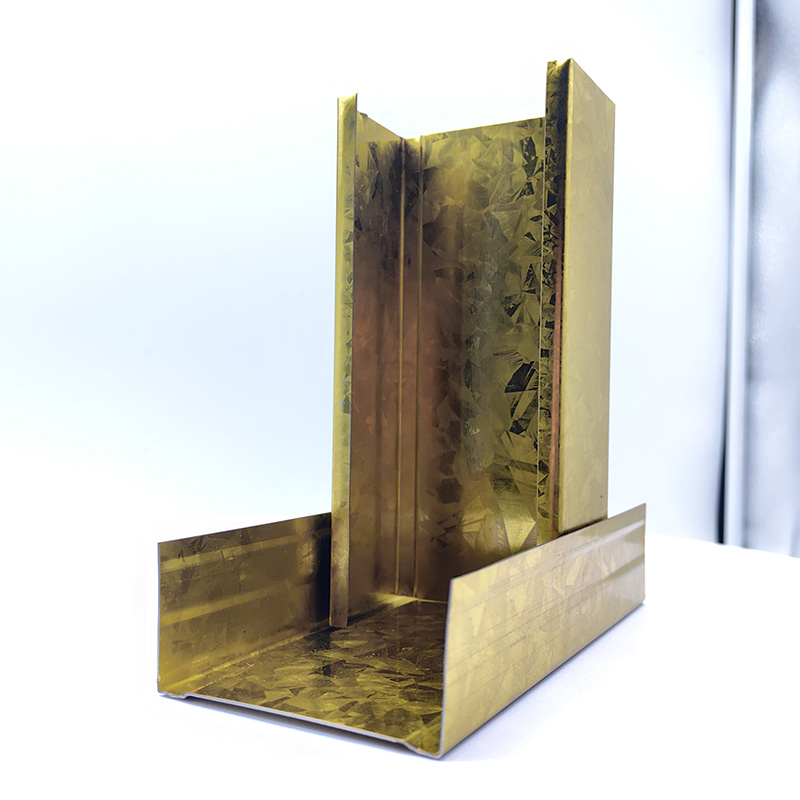

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...