Corner Wall Angle Geometry: Calculating Cuts for Seamless Drywall Transitions

2025-06-17 18:45:31

I. Introduction: Precise Calculation for Perfect Joining

In interior decoration projects, seamless joining of drywall is a crucial step in enhancing the aesthetic appeal and integrity of walls. The foundation of this lies in the precise calculation and cutting based on the geometry of corner wall angles. Accurate angle calculation not only ensures a natural and seamless transition of drywall but also effectively improves construction efficiency, reduces material waste, and cuts down on rework costs. This article will delve into the principles of corner wall angle geometry, systematically explain the methods for calculating cutting angles, and highlight key construction points to assist decoration professionals and DIY enthusiasts in achieving high - quality drywall installation.

II. Fundamentals of Corner Wall Angle Geometry

2.1 Types and Definitions of Corner Wall Angles

Corner wall angles are mainly divided into three types: right angles, acute angles, and obtuse angles. A right - angled corner, with an angle of 90 degrees, is the most common corner form. Its regular geometric characteristics provide a relatively standard reference for drywall installation. Acute - angled corners have angles less than 90 degrees and are often found in irregular spaces or specially designed areas. Obtuse - angled corners have angles greater than 90 degrees and are relatively common in some architectural structure renovations. Each angle type has its unique geometric features and measurement requirements.

2.2 The Relationship between Drywall Installation and Corner Wall Angles

Different corner wall angles directly determine the cutting method and joining angle of drywall. For right - angled corners, a 45 - degree joining cut is usually adopted to achieve a flat transition. For acute and obtuse - angled corners, the cutting degrees need to be precisely calculated according to the actual angles. Even a slight deviation can lead to large joining gaps, uneven surfaces, and other problems, seriously affecting the decoration effect and the stability of the walls.

III. Methods for Measuring Corner Wall Angles

3.1 Traditional Measuring Tools and Their Usage

A protractor is a basic angle - measuring tool. When using it, align the center of the protractor with the vertex of the corner and the base with the wall baseline. By reading the corresponding scale on the other side, the corner angle can be obtained. Combination squares are suitable for more complex measurement scenarios. By adjusting the included angle between their movable arms and straightedges, they can quickly measure corner angles and verify right angles, playing an important role in local measurements in interior decoration.

3.2 Advantages of Modern Electronic Measuring Tools

Digital angle finders use advanced sensor technology to quickly and accurately measure corner wall angles and display the results digitally, greatly reducing human reading errors. Laser angle measuring instruments, with their long - distance measurement and multi - point capture functions, show significant advantages in measuring large or complex corners, effectively improving measurement efficiency and accuracy.

IV. Methods for Calculating Cutting Angles

4.1 Cutting Calculation for Right - Angled Corners

For right - angled corners, the conventional 45 - degree joining cut method is used. Its calculation logic is based on geometric principles, dividing the 90 - degree right angle evenly into two 45 - degree angles so that two pieces of drywall can form a flat surface after joining. For double - layer drywall right - angled joints, the cutting angle needs to be adjusted appropriately according to the thickness of the boards to ensure that the two layers of drywall fit snugly and the joint is flat.

4.2 Cutting Calculation for Non - Right - Angled Corners

When cutting acute - angled corners, it is necessary to accurately measure the actual corner angle first and then obtain the cutting angle through geometric calculation. Generally, dividing the corner angle by 2 gives the cutting angle for a single piece of drywall. The calculation method for obtuse - angled corners is similar, but in actual operation, more precise control of the cutting angle and size is required to ensure a good joining effect.

4.3 Processing and Calculation Ideas for Special Corners (e.g., Curved Corners)

The processing of curved corners is relatively complex. It is necessary to determine the cutting shape through segmented measurement and curve fitting. A soft material can be used to make a template, and samples can be taken along the corner contour. Then, the drywall can be cut according to the template shape to achieve a seamless transition of the curved corner.

V. Selection and Usage Tips of Cutting Tools

5.1 Introduction to Common Cutting Tools

Utility knives are suitable for thin drywall or small - area cutting operations. They are flexible to operate and can perform fine straight - line or curved - line cutting. Electric drywall cutters, with their powerful power and precise cutting tracks, are more efficient in handling large - area and thick boards and can quickly complete straight - line cutting tasks.

5.2 Usage Tips and Safety Precautions for Tools

When using cutting tools, maintain a stable operating posture and a uniform cutting speed to ensure the straightness of the cut. To avoid edge chipping of the drywall, multiple shallow cuts can be used to gradually deepen the incision. At the same time, it is essential to wear protective equipment such as safety goggles and gloves and stay away from the area where cutting debris may fly to ensure construction safety.

VI. Key Construction Points for Ensuring Seamless Joining

6.1 Pre - Cutting Preparations

Before cutting the drywall, use measuring tools to accurately measure the wall dimensions and make marks on the board. When marking, use a pencil or a special scribing tool to ensure that the cutting lines are clear and accurate. Multiple checks and calibrations should be carried out to avoid dimensional errors.

6.2 Control during the Cutting Process

During the cutting process, auxiliary tools such as straightedges and guiding rules can be used to fix the cutting path and ensure the straightness of the cut. For curved cuts, the cutting trajectory should be planned in advance, and the cutting tool should be operated slowly. When cutting thick boards, cutting from both sides of the board simultaneously can reduce the risk of board breakage.

6.3 Details of Joining and Installation

Self - tapping screws can be used to fix the drywall at the joints. The screw spacing should be evenly distributed to avoid uneven local stress. The selection of joint - processing materials is crucial. Specialized joint compounds, joint tapes, and other materials should be used. Through filling, smoothing, and sanding processes, ensure that the joints are flat and smooth, achieving a true seamless transition.

VII. Common Problems and Solutions

7.1 Common Problems in the Cutting and Joining Process

Cutting angle deviation is the main reason for loose joining, which may be caused by measurement errors or improper operation of cutting tools. Dimensional errors in drywall cutting may result from inaccurate measurements, marking deviations, or shaking during the cutting process.

7.2 Targeted Solutions

If there is an angle deviation, secondary correction cutting can be performed on the already - cut drywall, or new boards can be measured, calculated, and cut again. For dimensional error problems, they can be remedied by filling with materials or re - cutting local areas to ensure precise matching of the joining dimensions.

VIII. Technological Development Trends

8.1 Application Prospects of Digital Calculation Tools

Software - based corner wall angle and cutting calculation tools are gradually becoming popular. Users only need to input the corner measurement data, and the software can automatically generate cutting plans and angle parameters, greatly simplifying the calculation process. In the future, intelligent measurement and calculation integrated devices are expected to achieve full automation of measurement, calculation, and cutting operations, further improving construction efficiency and accuracy.

8.2 New Cutting Technologies and Materials

Laser cutting technology, with its advantages of high precision and non - contact cutting, has broad application potential in the drywall processing field. At the same time, new drywall materials that are easy to cut and have high precision are also being continuously developed. These materials will reduce cutting difficulty and construction losses, bringing new changes to the decoration industry.

IX. Conclusion: Mastering Geometric Principles for Seamless Beauty

Corner wall angle calculation and drywall cutting are core technical links in decoration construction. From basic angle measurement, precise cutting calculation, to standardized construction operations and problem - solving, each step is crucial to the final decoration quality. With the continuous progress of technology, digital tools and new materials will bring more convenience to construction. It is hoped that the content of this article can help readers master key technologies, achieve seamless joining of drywall in actual decoration, and create perfect wall effects.

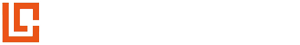

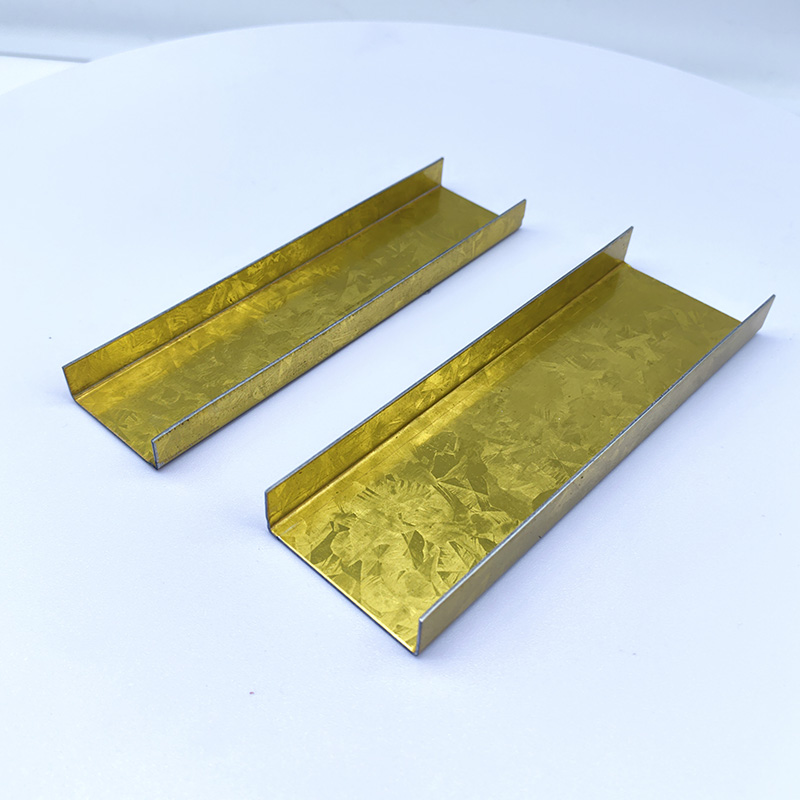

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

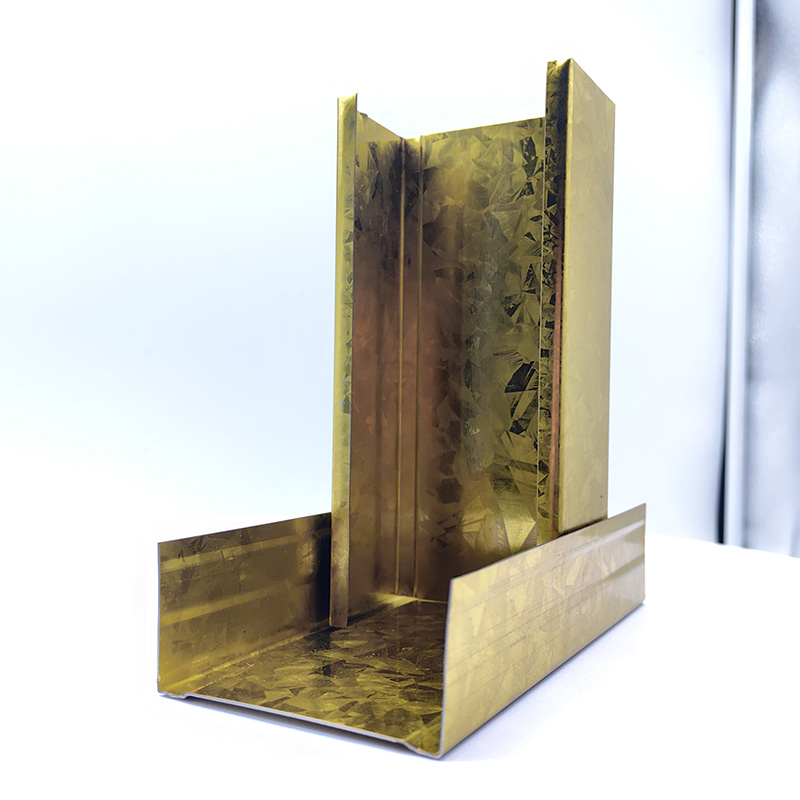

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

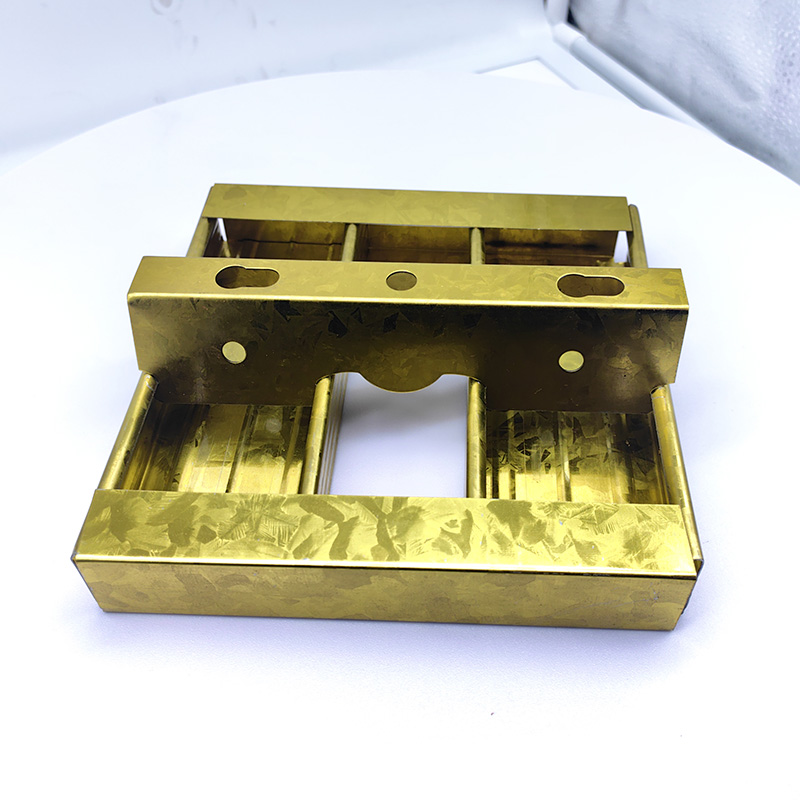

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...