Light Steel Ceiling Grid: The Ultimate Solution Combining Industrial Aesthetics with Functional Durability

2025-07-18 13:52:25

In the realm of ceiling materials, the light steel ceiling grid has gradually emerged as the ;invisible skeleton; for commercial spaces, public facilities, and high-end residences, thanks to its advantages of high strength, corrosion resistance, and ease of installation. Whether in modern architecture embracing minimalism or industrial spaces demanding high performance, the light steel grid redefines professional standards for ceiling systems through its multi-dimensional integration of ;structure + aesthetics + functionality;. This article delves into the core technical logic behind this material from three dimensions: material properties, design applications, and whole-life-cycle value.

I. Material Science: The ;Performance Genes; of Light Steel Grids

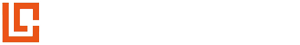

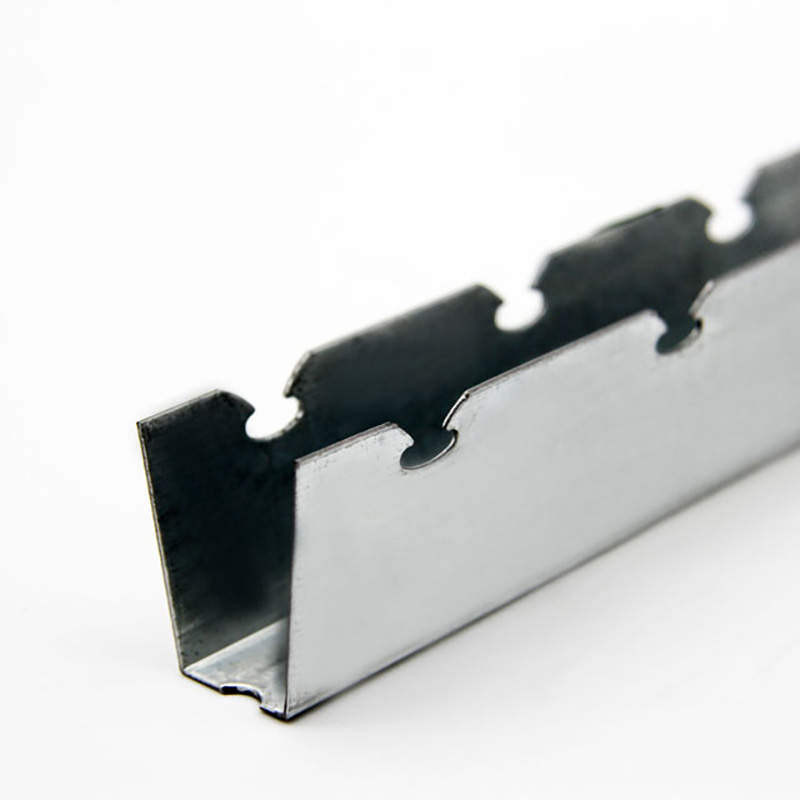

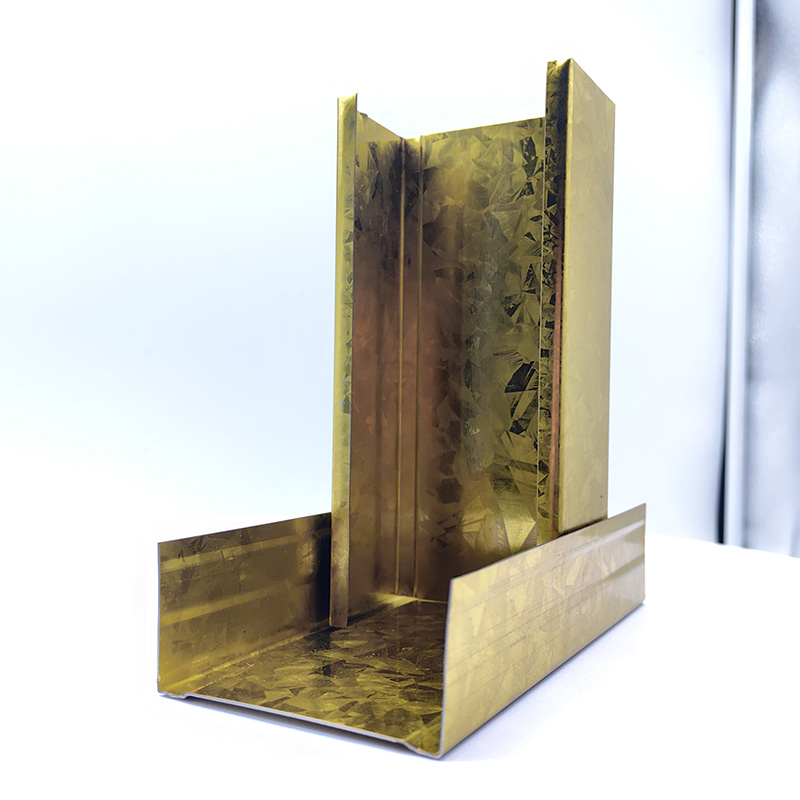

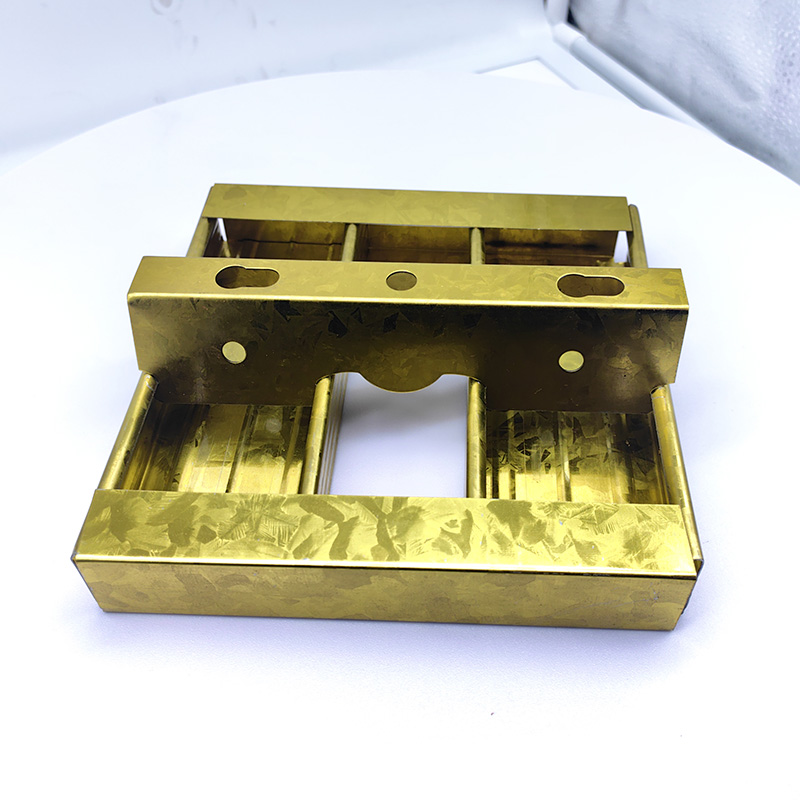

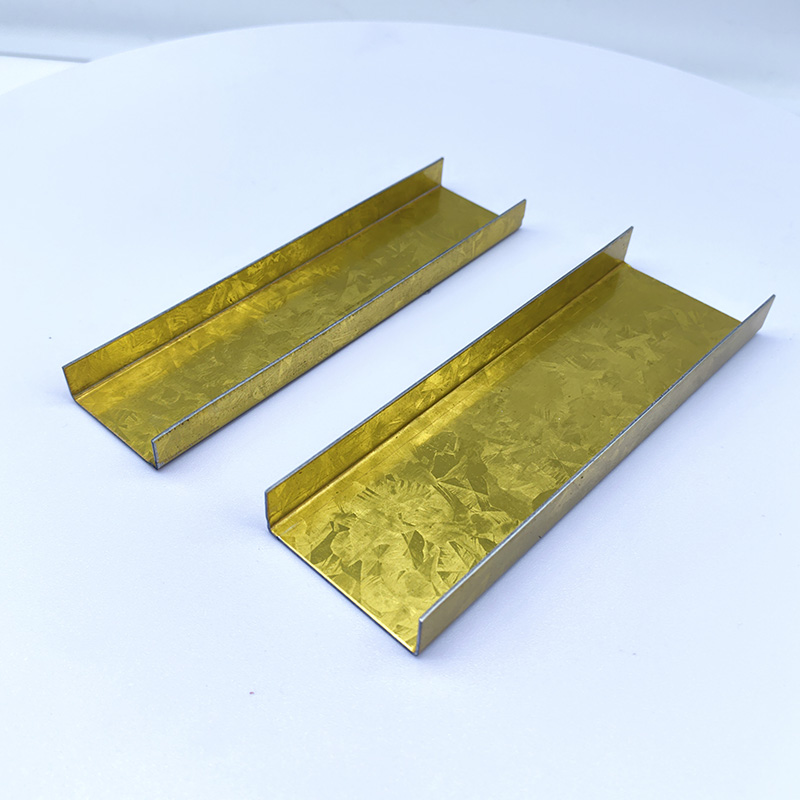

Light steel ceiling grids typically employ cold-rolled low-carbon steel (such as Q235) or hot-dip galvanized steel sheets as base materials, combined with stamping, welding, or snap-fit assembly processes to form modular systems with high load-bearing capacity and corrosion resistance. The core performance advantages are primarily reflected in the following three aspects:

1.Hot-Dip Galvanized Corrosion-Resistant Layer: Building a Durable Protective Barrier

The surface undergoes a hot-dip galvanizing process, achieving a coating thickness of 80-120μm, effectively resisting moisture, salt spray, and other corrosive factors. In high-humidity or coastal climates, it offers a service life exceeding 30 years, significantly reducing long-term maintenance efforts.

2.Grid Structure Reinforcement: Stable and Reliable Load-Bearing Capacity

The steel grid structure formed through pressure welding provides a load-bearing capacity exceeding 500 kg/m², suitable for installing ceiling-mounted auxiliary equipment such as air conditioning ducts and fire protection systems, meeting the demands of high-load environments.

3.Lightweight Design: Optimizing Building Loads

The grid structure maintains a self-weight of 4-6 kg/m² per layer, lighter than traditional solid ceiling systems, effectively reducing building structural loads by approximately 30% while enhancing installation efficiency.

II. Design Applications: Functional Integration and Stylistic Extension

Light steel ceiling grids boast excellent modularity, enabling flexible adaptation to the decorative language and functional requirements of different spaces, achieving an efficient configuration of ;invisible structure + visible functionality;.

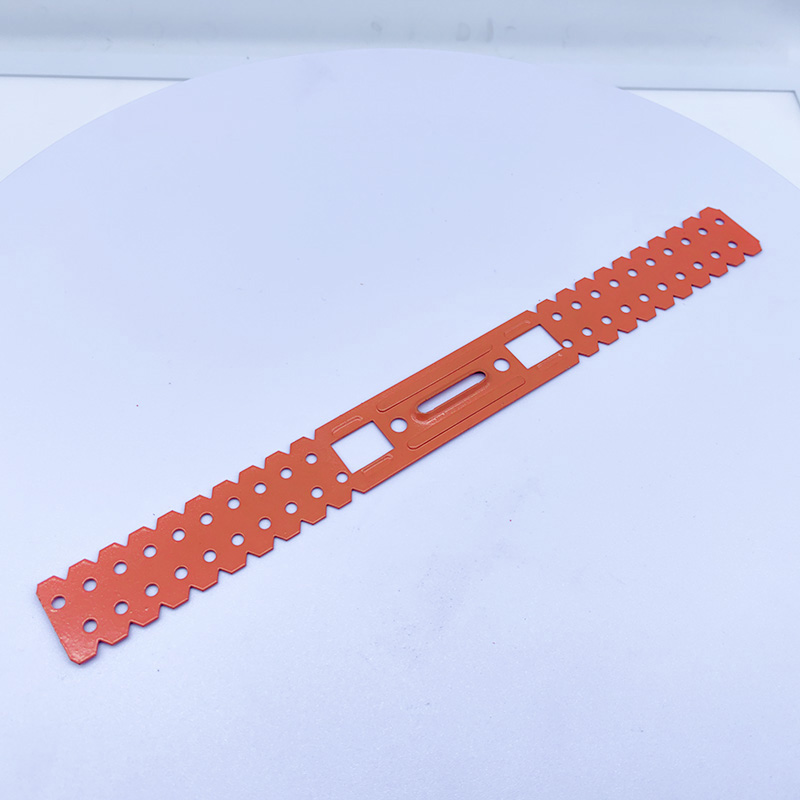

1.Industrial and Office Spaces: Modernity through Exposed Structures

Through treatments such as matte spraying and symmetrical arrangements, their linear order and structural aesthetics can be highlighted, commonly used in office parks, exhibition halls, and R&D centers to unify visual simplicity with equipment integration.

2.Commercial Spaces: Integrated Ceiling Solutions

In high-traffic areas like shopping malls and supermarkets, the grid structure facilitates the embedding of fire sprinklers, lighting fixtures, audio systems, and detectors, ensuring easy maintenance while providing excellent ventilation to optimize air conditioning energy distribution to some extent.

3.High-End Residences and Underground Spaces: Minimalist Invisible Systems

Combined with linear light strips and acrylic translucent materials, light steel grids can achieve a ;floating ceiling; design, enhancing spatial layering, suitable for residential scenarios such as basements and home theaters requiring structural concealment and localized lighting.

III. Long-Term Value: Significant Advantages in Whole-Life-Cycle Costs

Light steel grids not only exhibit high initial performance but also significantly outperform other types of ceiling systems over their entire life cycle.

1.Minimal Maintenance Requirements

The hot-dip galvanized surface eliminates the need for regular spraying or component replacement, requiring only periodic dust cleaning. A routine inspection and cleaning every five years are sufficient to maintain performance, resulting in extremely low annual maintenance costs.

2.Sustainable Recycling Value

Light steel materials are 90% recyclable, reducing building waste emissions and enhancing project sustainability ratings through green building credits (e.g., LEED, BREEAM), aligning with modern green building trends.

3.Whole-Life-Cycle Cost (LCC) Optimization

From procurement and installation to usage and maintenance, light steel grids offer a stable service life exceeding 30 years. Comprehensive calculations show that the system achieves excellent whole-life-cycle cost efficiency, particularly in large-scale engineering projects where durability and minimal maintenance are critical.

IV. Typical Application Scenarios: Ideal Choices for Diverse Environments

·Industrial Plants: Suitable for food, electronics, and chemical industries, meeting process requirements such as easy cleaning, dust prevention, and explosion protection.

·Transportation Hubs: Used in airports, high-speed rail stations, and subway stations with high load-bearing and ventilation demands.

·Healthcare and Education: Specialized antibacterial coatings for operating rooms and laboratories support cleanliness rating requirements.

·Commercial Offices: Integrated ceiling lighting and equipment while maintaining simplicity and maintainability.

International Standards and Quality Control

·To ensure global applicability, the production of light steel ceiling grids should comply with multiple international standards:

·EN 1090 (EU): Certification standard for the manufacture of metal structural components.

·ASTM A653 (US): Specification for zinc coating on steel sheets.

·ISO 9223/12944: Classification of corrosive environments and protective systems.

·GB/T 2518 (China): Technical specifications for hot-dip galvanized steel sheets.

·Through adherence to these quality systems, products can operate stably in various environments over the long term.

Conclusion: Structure as the Skeleton, Aesthetics as the Soul

As a novel ceiling system integrating structure, functionality, and decoration, the light steel ceiling grid is gradually replacing traditional single-function ceiling models. Its outstanding performance in load-bearing capacity, durability, system integration, and design expressiveness makes it an indispensable component in modern architectural spaces.

As a professional manufacturer of ceiling grids, we remain committed to technology-driven and quality-first principles, dedicated to providing global clients with safer, more aesthetically pleasing, and durable ceiling system solutions.

Recommended Reading (Technical References):

·Compilation of Research on the Performance of Structural Steel Materials in Architecture

·Handbook of Integrated Design for Modern Architectural Ceiling Systems

·Guide to Whole-Life-Cycle Assessment of Green Building Materials

·White Paper on Metal Corrosion Protection Technologies

·Case Collection of Smart Building Ceiling System Applications

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...